Bad Day: Clogged Drain Facilitates Spread of Radiological Contamination

A survey of the Waste Reduction and Packaging Area signaled the presence of contamination.

On November 5, 2018, a completed radiological survey of the Waste Reduction and Packaging Area (WRPA) dock and adjacent paved work area indicated contamination with the highest direct reading of 105,299 disintegrations per minute (dpm) beta-gamma per 100 square centimeters (cm2 ).

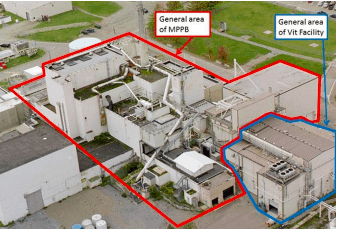

This area at the West Valley Demonstration Project had been previously controlled due to identified contamination from water found leaking from the Solvent Storage Terrace (SST) roof and through various places in the Main Plant Process Building (MPPB), eventually exiting the MPPB through the WRPA dock and running outside to uncontrolled paved work areas.. See our article on contamination here.

A radiation control technician observed that the water was tinted blue, indicating that it had come in contact with commercial-grade fixative recently applied to a facility within the MPPB. Staff identified that the water had flowed outside the WRPA dock, across the work area, and down to a drainage pipe that went under a roadway intersection.

Notifications were made and controls (ropes and barricades) were put in place to control the water and restrict access. Operations personnel were dispatched to the MPPB roofs to inspect for plugged drains. It was discovered that the SST roof drain was plugged. Once it was unplugged, water drained normally. There had been heavy rainfall the previous five days which totaled approximately three inches.

Lesson learned: Maintenance of facilities reviewed to avoid contamination

The lesson to be learned from this event is that the maintenance of facilities being deactivated for demolition must be carefully reviewed to consider the risks associated with reduced inspection or maintenance frequency.

Source: The Office of Environment, Safety, and Health Assessments (EA-30), within the Office of Enterprise Assessments (EA), performed a review of Occurrence Reporting and Processing System (ORPS) radiological events for recent deactivation and decommissioning (D&D) activities that had been identified by the site as having work process1 deficiencies (ORPS Report EM-OH-WVDP-CHBW-CF-2018-0004).

Founded in 1988, the TapRooT® Root Cause Analysis System solves hurdles every investigator faces

TapRooT® Root Cause Analysis Training System takes an investigator beyond his or her knowledge to think outside the box. Backed with extensive research in human performance, incident investigation, and root cause analysis, TapRooT® is a global leader in improved investigation effectiveness and productivity, stopping finger-pointing and blame, improving equipment reliability, and fixing operating problems.

System Improvements, the creator of the TapRooT® System, has a team of investigators and instructors with years of extensive training ready to offer assistance worldwide.

TapRooT® Root Cause Analysis Training courses are taught all over the world

If you are interested in learning how to stop repeat incidents, find a 2-Day or 5-Day course; or view the complete selection of TapRooT® courses. We are available to train you and your staff on-site at your workplace; Contact us to discuss your needs. You may also call us at 865.539.2139 to discuss any questions you may have.