Well Control Incident with Complications While Attempting to Cure Severe Losses (Bad Day)

A well control incident took place while preparing to sever the drill string above the plugged BHA and prevent severe losses.

| A well had experienced total and severe losses, conventional LCM pills were unsuccessful, resulting in the decision to pump a “total loss” LCM pill. Pill was under displaced, and BHA was not stripped above pill for fear of damaging the MPD annular. BHA became plugged. While preparing to severe pipe, the well flowed and was shut in. Bullheading was attempted but failed as pressure was kept low for hole integrity concerns. Pipe was severed above BHA, but circulation was still not possible. Additional LCM pills were pumped, followed by cement. Circulation regained. During Drillers Method circulation, high gas readings and oil contaminated mud seen and shakers. Circulation was stopped. No returns when attempting to restart circulation. Decision made to bullhead without concern for open hole. Well killed and cement plugs pumped. Open hole abandoned. |

Well control incident with complications while attempting to cure total and severe losses

| Drilling 8 1/2″ reservoir section using Managed Pressure Drilling, with hydrostatically underbalanced mud. Water zone with high pressure exposed in start of the section, oil reservoir with slightly lower pressure exposed further down. Two severe loss incidents experienced while drilling, reducing the drilling window to 0.3 ppg. Close to planned TD of the well, third severe loss zone encountered. LCM treatment unsuccessful. Decided to pump “total loss” LCM pill; under displaced pill and left BHA on bottom due to concerns with provoking a leak in MPD annular if stripping above the pill. Attempted circulation and observed string plugged. Mobilized severing equipment, meanwhile decided to shut in well to stabilize losses and preserve mud; closing the BOP removed the MPD back pressure, reducing the bottom hole pressure. Loss rate decreasing and levelling out while waiting for equipment.While preparing to sever string above BHA, observed gain and shut in well again. Attempted cautious bullheading, limited by integrity of previous loss zone, unsuccessful. Severed string above BHA and attempted Driller’s method, unable to establish returns.Pumped LCM and cement and achieved formation integrity for circulating. 2nd attempt of Driller’s method stopped due to early arrival of high gas readings at shakers, and heavily oil-contaminated mud. No returns when re-starting circulation. Decided to bullhead well without constraints towards formation integrity, loss of section accepted. Placed cement plugs in open hole. |

What went wrong?

| Higher pressure than predicted in water zone early in 8 1/2″ section. Several loss incidents due to lower formation strength than predicted – drilling window severely reduced.Well control response delayed due to plugged string with LCM. While waiting for severing equipment with well shut in on BOP, MPD back pressure was removed and thus bottom hole pressure reduced, allowing x-flow from high pressured water zone into the loss zone at TD. Hydrostatic column weight was thus reduced and influx from oil zone allowed. Actual bottom hole pressure increasingly uncertain due to mixture of fluids.After communication through drill string achieved by severing, Driller’s method attempts with unstable pressures due to deteriorated mud allowed additional influx in well. |

Corrective actions and recommendations for severe losses incident

| Ensure to over displace a “total loss” or “severe losses,” LCM pill and flush string afterwards.Pressure limit on first bullheading attempt was too low, assuming uniform mud column all the way; actual bottom hole pressure in the annulus was likely lower, due to lighter fluids (water and oil) having entered the wellbore.Well control options constrained by attempts to save the section for subsequent wireline logging objective.Closing the BOP in a loss situation shall be thoroughly evaluated as it may cause underbalance in the well. |

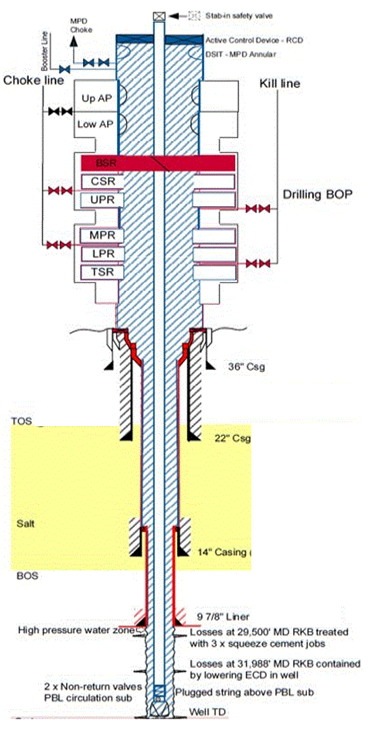

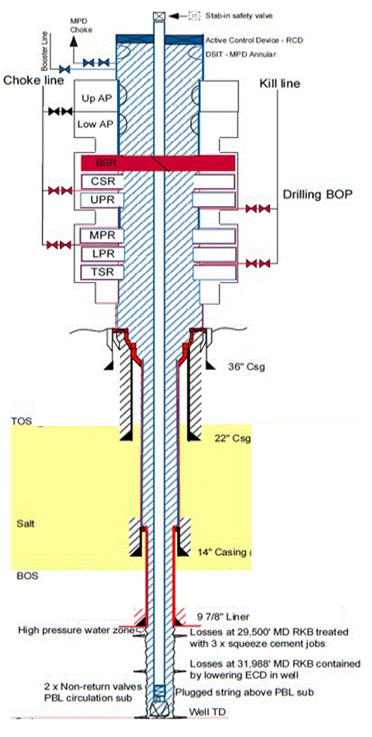

Figure 1: Well barrier schematic at time of incident

Well barrier schematic illustrating the barrier elements during an MPD operation. Note: BSR was not closed during the incident, it is only shown here as closing the secondary barrier envelope. |

Source: IOGP WCI Lesson Sharing 22-4, IOGP (International Association of Gas & Oil Producers).

Founded in 1988, the TapRooT® Root Cause Analysis System solves hurdles every investigator faces

TapRooT® Root Cause Analysis Training System takes an investigator beyond his or her knowledge to think outside the box. Backed with extensive research in human performance, incident investigation, and root cause analysis, TapRooT® is a global leader in improved investigation effectiveness and productivity, stopping finger-pointing and blame, improving equipment reliability, and fixing operating problems.

System Improvements, the creator of the TapRooT® System, has a team of investigators and instructors with years of extensive training ready to offer assistance worldwide. We also offer ongoing support to our clients through free newsletters and root cause tip videos, the root cause analysis blog, and our annual Global TapRooT® Summit.

Register for a TapRooT® RCA Course

Register for one of our TapRooT® courses. Among all the TapRooT® Training courses, we offer a 2-Day TapRooT® Root Cause Analysis Course and a 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Course.

Contact us or call us at 865.539.2139 about having a course at your site or for further root cause analysis training opportunities. We’re here to help you find solutions.