The Best Root Cause Analysis Toolkit Review

Toolkit for Root Cause Analysis

What’s the best for root cause analysis toolkit? Read on and see. We outline the tools that we think are the best for your root cause analysis toolkit.

Read about:

- Defining a root cause

- A process to connect your tools

- An “understanding what happened” tool

- Optional evidence-collection tools

- A Causal factor definition tool

- A guided root cause analysis tool

- A Generic Cause analysis tool

- A tool to present your results

- How the best root cause analysis toolkit was developed

After you read about this optimum toolkit, you will understand more about the fundamentals of root cause analysis and incident investigation, and you will want to order a book or register for a course.

Before You Build a Toolkit, Define a “Root Cause”

Before you can build a root cause analysis toolkit, you have to define what you are looking for – a root cause.

Back in 1985, when David Busch and I started looking for ways to find root causes, we weren’t the first to define a “root cause.” There was already a dictionary definition. The online Collins Dictionary defines a root cause as:

“The fundamental reason for the occurance of a problem.”

The Collins Dictionary says that the first recorded usage of “root cause” was in the late 1800s and that the term is one of the 30,000 most used words in the dictionary.

However, we thought the definition needed to be more specific, so we started developing our own definition. Our first definition, first used in 1985 and published in 1986, is shown below…

ROOT CAUSE

The most basic cause (or causes)

that can reasonably be identified

that management has control to fix.

We quickly found that not everyone agrees with this definition. However, several key ideas sprung from the definition that became the bedrock upon which the TapRooT® Root Cause Analysis System was built (and from which many other definitions were developed across many industries).

FIRST, when one finds a root cause, one has found something that, when corrected, will fix the problem. This is a key because it keeps one looking for a FIXABLE SOLUTION.

SECOND, our definition targets problems within management’s grasp to fix. For example, one might say that gravity is the root cause of a fall. However, this would not be a root cause by our definition because management can’t fix gravity.

THIRD, our definition helps answer the always-troubling question of how much investigative effort is enough. This question comes down to a trade-off between a “REASONABLE” effort (usually defined as the least possible effort) and finding the “MOST BASIC” cause(s) (sometimes seen as a never-ending quest if people can’t agree on the definition of a “basic cause”). The final arbitrator between these two competing priorities (timeliness and completeness) is the requirement to find fixable causes that, when corrected, will prevent the incident’s recurrence. Therefore, an investigator has expended a “reasonable” effort if one has identified the FIXABLE CAUSES OF AN INCIDENT.

FOURTH, the definition implies that a problem MAY HAVE MORE THAN ONE ROOT CAUSE. In our early experience investigating and reviewing hundreds of incidents, we found that, on average, incidents had two to three root causes per simple incident (a simple incident is one with one or two Causal Factors). In our experience with more complex incidents in more complex systems (with multiple Safeguards and multiple Causal Factors in the incident), we might find ten or more root causes (things that can be improved) in a single, complex incident.

Allowing for multiple root causes stops arguments over which cause is the “rootiest” of the root causes. Any cause for a problem that fits the definition is one of the root causes of the problem that can be fixed.

Our definition was the jumping-off point in the search for a toolkit that helps problem solvers find fixable root causes.

But we didn’t stop with our 1986 definition. We continuously improved it. By 2006, we decided to completely overhaul the definition to make it much more positive and focus on best practices that could stop problems from occurring. The modern definition we now use is:

MODERN DEFINITION OF A ROOT CAUSE

The absence of a best practice

or the failure to apply knowledge

that would have prevented the problem.

Rarely does an accident happen that we didn’t already know how to prevent it. The absence of a best practice or the failure to apply the knowledge that we already possess allows an accident to occur.

All our definitions guided us when developing a root cause analysis toolkit (a systematic process for finding root causes). This helped us develop our tools and build them into a robust, systematic root cause analysis process.

You Need A Process That Connects Your Tools

When we started looking for and developing root cause analysis tools, we thought of them as handy tools that a master root cause analyst would use. The analyst would know which ones to use and when. The tools weren’t connected.

When we wrote the first TapRooT® Manual in 1991 (shown below), we realized that the tools were connected – part of a process.

By 2015, when we started writing our most recent ten-book set, we had developed three processes. One for simple incidents, one for equipment failure investigations, and one for major accidents. The simple incident process is on the left and the major accident process is on the right.

The third process was a modification to the simple incident process to make a process for investigating equipment failures (shown below).

We aimed to make it easy to investigate simple incidents and equipment failures and provide all the tools needed for major accidents. The processes give the investigator guidance on which tools to use and when.

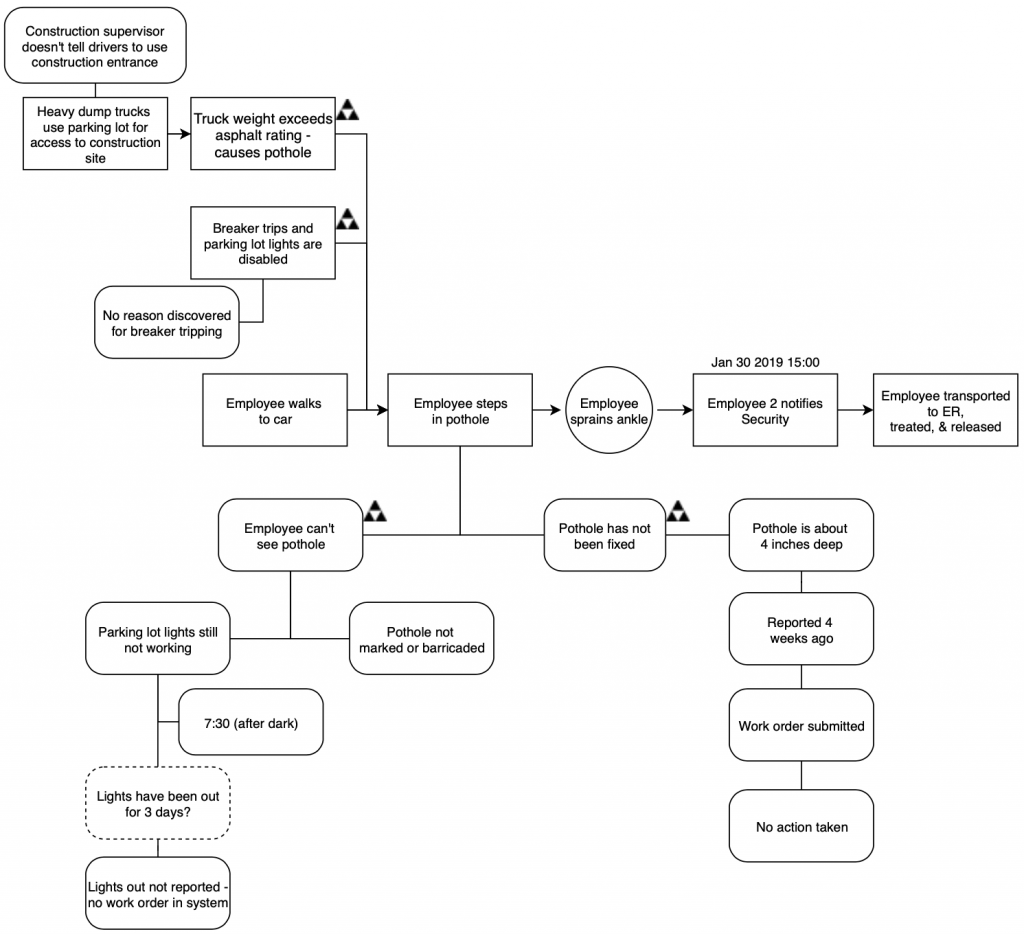

A Tool to Help You Understand What Happened

One of the first tools used in any investigation (simple, equipment, or major) is the SnapCharT® Diagram. The SnapCharT® Diagram provides a place to display the information you collect and understand what happened. An example of a SnapCharT® is shown below…

We think it is essential to understand what happened BEFORE you try to determine WHY it happened (the root causes).

Failure to understand what happened before you ask why is one of the major drawbacks of many root cause analysis tools.

Optional Evidence Collection Tools

The TapRooT® 7-Step Major Investigation Process has three optional tools to help investigators collect information about an incident/accident. They are:

- Equifactor®

- Change Analysis

- Critical Human Action Profile (CHAP)

They were added to the process to provide investigators with specialized tools for particular types of investigations.

Equifactor® was developed specifically for the TapRooT® System with the help of equipment reliability expert Heinz Bloch to help investigators troubleshoot equipment failures and understand the underlying physical causes.

Change Analysis was adopted for use in the TapRooT® System by permission of the System Safety Development Center to help people analyze how changes could have led to an incident.

CHAP was developed for use by the US Nuclear Regulatory System and the TapRooT® System to help investigators collect information and understand human errors that led to incidents.

In the TapRooT® Advanced Root Cause Analysis Team Leader Training, each technique is reviewed in detail and demonstrated in an example.

Also, the TapRooT® Advanced Root Cause Analysis Team Leader Training and the 2-Day Effective Interviewing & Evidence Collection Course offer techniques for conducting interviews effectively (the 14-Step Cognitive Interviewing Process) and guidance for evidence collection and preservation. These techniques help make the tools and processes more effective.

A Tool to Find Root Causes

Perhaps the most powerful tool at the heart of the TapRooT® Toolkit is the TapRooT® Root Cause Tree®.

What does the Root Cause Tree® do for an investigator? It guides the investigator from a Causal Factor to its root causes. Guided root cause analysis is a much more powerful way to find root causes. Read more about guided root cause analysis at THIS LINK.

Or watch this video where Benna and Mark discuss guided root cause analysis…

A Tool to Help Find Generic Causes

A Generic Cause is:

GENERIC CAUSE

The systemic cause that allows a root cause to exist.

Fixing the Generic Cause eliminates whole classes

of specific root causes.

Finding Generic Causes is step five in the TapRooT® 7-Step Major Investigation Process and an optional step in the simple investigation process. The Corrective Action Helper® Guide/Software Module helps the investigator find Generic Causes.

A Tool to Develop Corrective Actions

The main purpose of the Corrective Action Helper® Guide/Software Module is to help investigators recommend effective corrective actions to prevent the incident’s recurrence.

The Guide has four major sections for each root cause on the Root Cause Tree®. They are:

- Check: The first step is to check that you have truly identified a root cause.

- Corrective Action Ideas: Provides suggestions for developing effective corrective actions.

- Generic Cause Corrective Action Ideas: Provides suggestions for addressing the Generic Causes.

- References: Provides references to learn more about this root cause and corrective actions.

A Tool to Help You Present Your Results

Investigators usually present their investigation results to management. The SnapCharT® Diagram is a great tool for explaining what you have found.

In addition, the TapRooT® Software provides a preset report to show your Causal factors and Corrective Actions. This report can easily be customized to meet your company’s format and needs.

Why Is the TapRooT® System the Best Root Cause Analysis Toolkit?

We spent years developing the first TapRooT® System and Manual. We’ve spent decades improving the system and books.

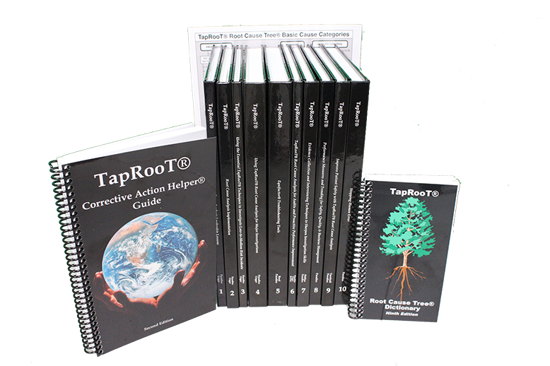

The first three generations of TapRooT® Documentation are shown above. In 2020, we completed writing the new 10-book set, shown below.

You can order the ten-book set HERE.

The TapRooT® System started with research into root cause analysis best practices and the human factors research behind why people make mistakes. This information was used to develop a system that was tested in the field and reviewed by experts. Over the next 30 years, System Improvements refined the system by testing, feedback from trainees, and advice from the 50-member TapRooT® Advisory Board, which comprises users from different industries from around the world. To read more about the history of the development of TapRooT®, visit the HISTORY PAGE on this website. It explains the over 30 years of research and development and the scientific basis of the TapRoot® System.

We based the system on proven engineering experience and human factors research that was developed into a guided root cause analysis process and tools that have been thoroughly tested, improved, and reviewed and have even more years of continuous improvement and software development to make the system even more usable. This process yielded the world’s best root cause analysis toolkit. A single system with software that covers all your root cause analysis needs.

How Can You Learn About the TapRooT® Root Cause Analysis Toolkit?

While you are working from home, perhaps a book is the best way to get started. Book 4: TapRooT® Root Cause Analysis for Major Investigations covers the process and tools for major investigations. Or you could buy Book 3 (Using the Essential TapRooT® Techniques to Investigate Low-to-Medium Risk Incidents) and Book 4 at the same time at THIS LINK.

The fastest way to get started using TapRooT® TCA is to attend one of our 2-Day TapRooT® Root Cause Analysis Courses. To learn the complete TapRooT® Root Cause Analysis System, attend a 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Training. And to learn advanced equipment troubleshooting skills and root cause analysis, attend the 2-Day Equifactor® Equipment Troubleshooting and TapRooT® Root Cause Analysis Course. You can attend one of our public courses or schedule a course at your site. CONTACT US for a quote.

Whatever you do … Don’t miss these highly-rated courses! You need the best root cause analysis toolkit to improve performance at your facility.