Beyond Human Error as a Root Cause

Beyond Human Error as a Root Cause

• • •

I’ve seen many root cause analyses that end with “human error” as the root cause. In this article, we will explore human error as a root cause and see how you can go beyond human error when identifying root causes.

We will explore:

- Why human error is not a root cause

- Going beyond human error as a root cause

- Becoming proactive to prevent human errors

- How you can learn to find the root causes of human errors

- How you can be proactive to prevent human errors and avoid incidents

Read on to discover proven ways to stop human errors.

Why Human Error is NOT a Root Cause

Before you can say whether human error is or is not a root cause, you need to define a root cause. In the TapRooT® Books, we define a root cause as:

“The absence of a best practice or the failure to apply

knowledge that would have prevented a problem.”

This is our most modern definition. CLICK HERE for the history of this definition.

A human error is NOT the absence of a best practice or the failure to apply knowledge that would have prevented a problem. Instead, human error fits much better into the definition of a Causal Factor:

Causal Factor:

A mistake, error, or failure that directly leads to

(or causes) an Incident (the circle on the SnapCharT®) or

fails to mitigate the consequences of the original error.

Most human errors are mistakes, errors, or failures. Thus, a Causal Factor is where a TapRooT® User starts their search for root causes. For more about the identification of Causal Factors, see:

Going Beyond Human Error as a Root Cause

How do you go beyond human error—beyond a Causal Factor? That’s easy. You use the TapRooT® Root Cause Tree® to guide you to the root causes of human errors.

What is the Root Cause Tree®, and how does it work? It is an 8.5″ by 11″ guide (also implemented in the TapRooT® Software) that provides an expert system for finding the root causes of human errors.

First, if there is a human error, the investigator identifies it as a “Human Performance Difficulty.” (We try to avoid the term “human error,” as that tends to lead to blame.)

Answering the 15 questions leads the investigator to topics to investigate in more detail and reduces blame because it guides investigators to fixable root causes. An example of one of the 15 questions is:

The topics to investigate in more detail are called Basic Cause Categories. There are seven of them:

- Procedures,

- Training,

- Quality Control,

- Communications,

- Human Engineering,

- Work Direction, and

- Management Systems.

If one of the 15 questions indicates a category, the investigator uses evidence in a process of elimination and selection guided by the questions in the Root Cause Tree® Dictionary.

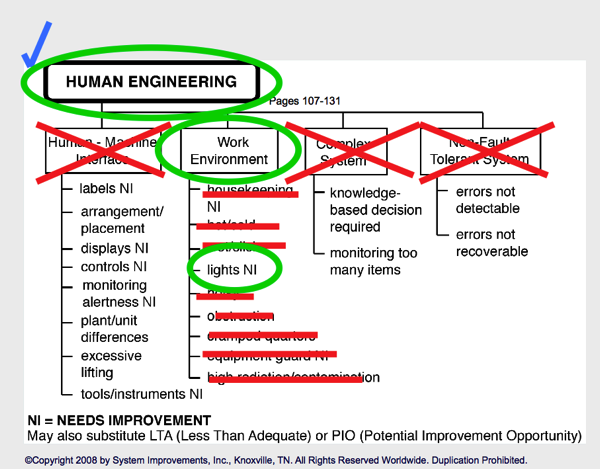

Usually, more than one Basic Cause Category is indicated as a possibility. The investigator uses evidence to work their way down the tree until a root cause, or causes are discovered under the indicated categories or until that category is eliminated. Here’s the Human Engineering Basic Cause Category with one root cause indicated (Lights NI).

The process of using the Root Cause Tree® was tested by users in several different industries, including a refinery, an oil exploration division of a major oil company, the Nuclear Regulatory Commission, an airline, and a hospital system. In each case, the tests proved that the Root Cause Tree® helped investigators find root causes that they previously would have overlooked and improved the company’s development of more effective corrective actions.

Would you like to see some success stories written by TapRooT® Users? See these links:

Or watch this video to learn about three stories…

Learn to Prevent Human Errors

Once the investigator (or team) has identified the root causes, they are ready to develop corrective actions to remove the Causal Factors (human error) and prevent the recurrence of the incident. TapRooT® provides ideas for each root cause in the Corrective Action Guide (the Corrective Action Helper® Module in the TapRooT® Software).

TapRooT® also helps the investigators identify Hazards and/or Targets that need to be removed to reduce risk.

The goal of the corrective actions is to reduce/eliminate human error or to improve the reliability of the system by making human errors unlikely or easy to spot and correct before an incident happens.

Learn to Become Proactive to Prevent Human Errors

Many people believe you must wait for an accident or incident to apply root cause analysis to fix problems. However, the TapRooT® System can be applied proactively to improve human performance and stop human errors. We even wrote a book about how to do it:

Click on the link above to learn more.

What Course Should You Attend?

There’s only so much information you can put into an article. The best way to learn about stopping human error is to attend our courses.

First, to apply TapRooT® Root Cause Analysis in investigating a safety, quality, equipment reliability, production, or construction incident, you should attend the 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Training. We hold public courses all over the world, and we can hold one at your site. For information about holding a course at your site, contact us by CLICKING HERE. To see where we are holding public courses around the world, see this link:

https://store.taproot.com/5-day

Attend the 2-Day Stopping Human Error Course to implement a program to improve human performance and prevent human errors before accidents happen. We can hold this course at your site, or you can attend one of our public Stopping Human Error Courses.

Register Today

If you want to attend one of our public courses, see the complete list of upcoming public courses HERE. Register today because you need to stop human errors/improve human performance to make your company safer and more productive.