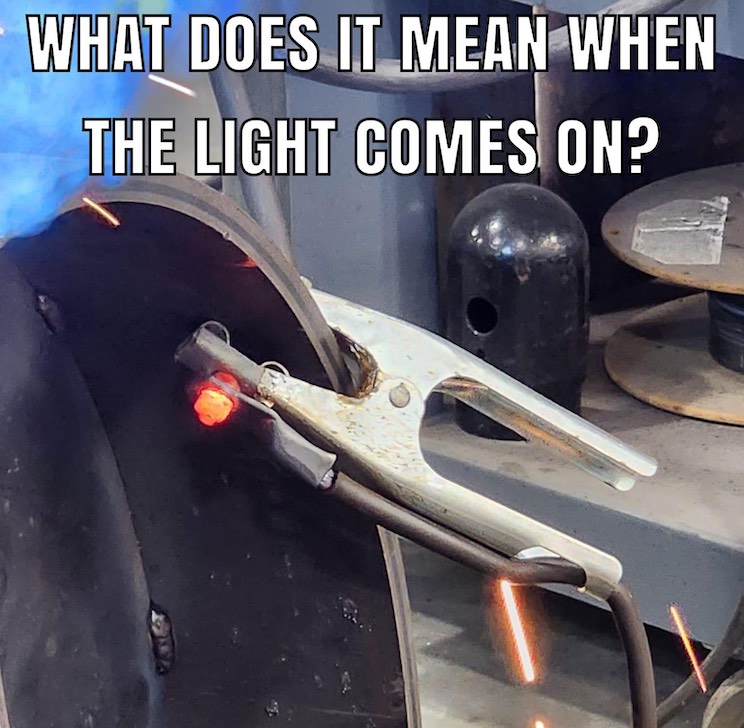

Friday Joke: What does it mean when the light comes on?

Speaking of when the light comes on, those are the exact words a professor used in a course when he was defining “perception.”

Also, you might go as far as to think of TapRooT® RCA’s Ken Reed, Justin Clark, and Equifactor® Troubleshooting when you’re thinking/talking about when the light comes on.

Do you need to efficiently and effectively find the root causes of equipment failures to end your unplanned outage YESTERDAY?

Is your equipment reliability program basically a fire department?

Does an economic downturn mean that only best-in-class performers survive?

Imagine the downtime prevented and money saved by using true first-time fixes and NOT having repeat equipment failures. If this sounds interesting (and worthwhile), then Equifactor® Equipment Troubleshooting & TapRooT® Root Cause Analysis is for you.

Equifactor® techniques are based on the work of the late equipment reliability expert Heinz Bloch and capture how Best-in-Class Performing organizations think differently about their equipment and systems.

In two days, you will learn:

- How to use Equifactor® to troubleshoot equipment failures

- Maintenance and operational best practices

- Holistic, proactive system reliability techniques to ELIMINATE the reasons (plural) equipment failures occur

The tools you will learn include:

- Equifactor® Troubleshooting Tables – a systematic guide to troubleshooting common equipment problems. Don’t guess – prove!

- Troubleshooting Strategy – don’t lose the data! Develop a troubleshooting plan to capture all failure symptoms, possible causes, and eliminate all causal factors.

- Failure modes / failure agents – there are only four ways a physical component can fail. Don’t FRETT, build the equipment failure narrative (hint, it’s never just a single point failure)

- Custom Tables – The best use of Equifactor®! If there’s no tables, build them, capture the wisdom of your machine whisperers, build the perfect training document for new equipment troubleshooters, and cut the troubleshooting turnarounds in way less than half by structuring it.

- Proactive Improvement – true solutions are always proactive even if they’re motivated by a failure. If you truly fix a problem, failures don’t recur!

- Change Analysis – “It was working and now it isn’t” or “the other machines are working, what’s different about this one?” Change analysis structures the intuitive but messy process of comparing machine failures to past performance or similar equipment.

- Root Cause Analysis – Walk through a root cause analysis to prove the human performance root causes of equipment failure.

Equifactor® is for technicians, equipment reliability specialists, maintenance managers, and non-equipment expert investigators. Develop best-in-class performance by asking best-in-class questions.

Course Outline

DAY ONE

- Introduction

- Equipment Troubleshooting – Understanding the Problem

- Structured Troubleshooting

- Equifactor® Troubleshooting Tables

- Troubleshooting Plan: first-time fixes

- Exercise – Developing a troubleshooting strategy for the pump

- Custom Troubleshooting Tables

- Custom Table Exercise – student incident equipment or clothes dryer

- Proactive Equifactor

- Failure Modes/Failure Agents

DAY TWO

- Change Analysis

- Causal Factors

- Root Cause Tree

- Turbine Pump Exercise

- Team Exercise

The course materials include the book, Using Equifactor® Troubleshooting Tools and TapRooT® Root Cause Analysis to Improve Equipment Reliability, a TapRooT® Root Cause Tree®, the Root Cause Tree® Dictionary, and the Corrective Action Helper® Guide, a $129 value. The book includes a complete set of Heinz Bloch’s troubleshooting tables.

Upon course completion, attendees receive a certificate and a 90-day subscription to TapRooT® VI Software, our dynamic cloud-based software that computerizes Equifactor® and TapRooT® Techniques.