Guided Root Cause Analysis

What is Guided Root Cause Analysis?

Do you need guided root cause analysis? Below, we discuss:

- The Wagon Train Analogy

- Picking Guided or Unguided Root Cause Analysis

- How Does TapRooT® Root Cause Analysis Guide You?

- Guidance from the Root Cause Tree® Diagram

- Guidance from the Equifactor® Troubleshooting Tables

- Guidance built into TapRooT® VI Root Cause Analysis Software

- Learn More About Advanced, Guided Root Cause Analysis

Below is the complete original article. But first, here is a video that explores the concept in a little more than 15 minutes.

Now, if you are interested, read on for the difference between guided root cause analysis and brainstorming or cause-and-effect (unguided root cause analysis) and how it impacts the results of your incident investigations.

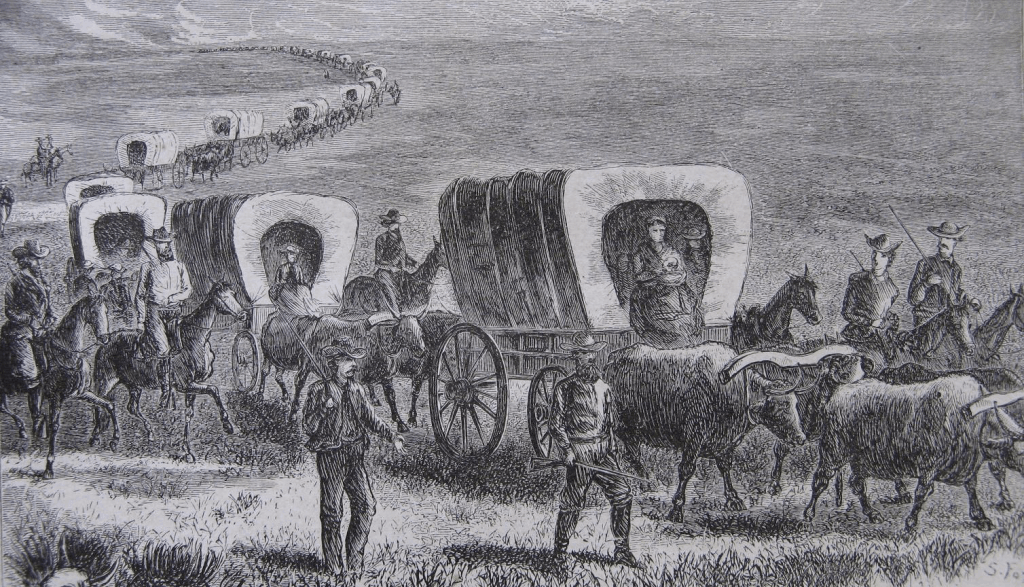

Wagon Train Analogy

Do you need a guided process for root cause analysis?

Let’s think about an analogy … say it was back in the 1800s and you had loaded up your Conestoga wagon to “Head west, young man!” across the plains and mountains of the United States (and its territories).

Would you head out all by yourself? Or would you join a wagon train?

If you joined a wagon train, would you want it to be a leaderless group of wagons that had never been where they are going and didn’t have a map? Or would you rather hire an experienced wagon master who had a map, had experience on the trail you wanted to take, and had led several successful previous wagon trains to the destination where you were headed and came highly recommended?

Which option has the most likelihood of success?

Picking Guided or Unguided Root Cause Analysis

Pick one of these options for your next root cause analysis:

OPTION 1. You use your knowledge and hope to find the root causes of incidents and accidents by asking “Why?” multiple times.

OPTION 2. You have your experience finding human factors root causes and troubleshooting equipment. Before you start your investigation, you develop your own troubleshooting guides for all types of equipment and a guide for analyzing human factors issues. You then use your knowledge and experience that you have gathered with the tools you developed to find the root causes of your next incident by just digging in and thinking about what went wrong — no preconceived notions for you – just your knowledge and hard work.

OPTION 3. You know someone who has/is:

- A team of experts that developed equipment troubleshooting and human performance root cause analysis guidance.

- Put that guidance into a systematic, repeatable process.

- Systematically tested the process and tools and improved them before letting you use them.

- Documented the process and put it into a set of books that clearly describes how it is used.

- Developed training with realistic examples.

- In the training, lets you test the process on an incident from your facility.

- Willing to teach you all the secrets of using the process.

- Ready to coach you if you have any trouble applying the process.

What do you think? Which one would be better for you? Which one is most likely to succeed?

Can you see the similarity between the guided wagon train and the guided root cause analysis (Option 3)?

Option 3 is what you get when you attend TapRooT® Root Cause Analysis Training and apply the TapRooT® Root Cause Analysis System when you perform your next incident investigation.

How Does TapRooT® Root Cause Analysis Guide You?

First, it starts with a process (actually two processes) and proven tools.

The first process is for low-to-moderate risk incidents that have the potential to be worse (precursor incidents). The process for investigating these “simple” incidents is shown below.

This process helps you perform good, fast investigations using the TapRooT® Root Cause Analysis Tools. Tools that also provide guidance. (More about that later.)

What about guidance for major investigations? You start with the process below.

This process is slightly more complex but provides the guidance needed when a major accident needs a thorough, credible root cause analysis.

Guidance from the Root Cause Tree®

Several of the tools help guide the investigator but the one we will discuss here is the Root Cause Tree® Diagram. The Root Cause Tree® is used in both of the processes above.

The Root Cause Tree® Diagram uses an expert system to guide investigators to the root causes of human errors and equipment failures.

The tree has a Human Performance Troubleshooting Guide with 15 questions to help the investigator decide where potential root causes may be lurking. What kind of questions? Questions that a human factors expert might ask. For example, see number 1 below:

Do you consistently look into fatigue, impairment, and distractions as part of your investigation of human errors? That’s the kind of guidance you receive when using TapRooT® RCA.

The guidance continues with the Basic Cause Categories (seven of them) on the Root Cause Tree®. An example of one category, Human Engineering, is shown below.

The terms used in the Root Cause Tree® Diagram are defined by questions that an investigator should be able to answer. These questions are in the Root Cause Tree® Dictionary.

How do we know we have the right questions in the Guide, on the Tree, and in the Dictionary to guide your investigation? Simple … expert development, review, and testing.

Mark Paradies, Linda Unger, David Busch, and Dr. Paul Hass were among the initial developers. Their initial development was followed up by reviews by many human factors and root cause analysis experts including Dr. Charles O. Hopkins, Dr. Jens Rasmussen, Smoke Price, Dr. Alan Swain, Jerry Leaderer (first head of the forerunner of the NTSB), Larry Minnick, Heinz Bloch, Dr. Ann Ramey-Smith, Dr. Barclay Jones, and Dr. Joel Haight.

But the excellent development and review by experts weren’t all there was. There was extensive user testing. It started with reviews of hundreds of incidents to test the system. That was followed by field user testing. This was followed by suggested improvements and reviews by the TapRooT® Advisory Board (currently 65 TapRooT® Users from around the world).

The improvement of the Root Cause Tree® Diagram has progressed for 30+ years and continues to this day.

Guidance from the Equifactor® Troubleshooting Tables

The Root Cause Tree® Diagram isn’t the only tool in the TapRooT® System that provides the investigator with guidance. We used the knowledge of Heinz Bloch, equipment reliability guru, to develop the Equifactor® Troubleshooting Tables. These tables (a list provided below) provide expert troubleshooting guidance for pumps, compressors, fans, blowers, engines, electric motors, refrigeration units, conveyor belts, valves, bearings, gears, gear couplings, mechanical seals, and electrical components.

The guidance for troubleshooting a centrifugal pump with insufficient capacity is shown below.

In this case, the troubleshooting result was the discovery that the impeller was installed backward. Many other causes were eliminated in the process of finding this problem.

Guidance from the TapRooT® Root Cause Analysis Software

All the guidance from the TapRooT® System is built into the TapRooT® VI Software. That guidance includes:

- The simple and major investigation processes

- Equifactor® Equipment Troubleshooting

- The SnapCharT® Diagram Module

- The Root Cause Tree® Module and Dictionary

- CHAP, Change Analysis, and Safeguard Analysis Modules

- The Corrective Action Helper® Module

All of these tools and their guidance are provided in an easy-to-use interface. Find out more about the TapRooT® VI Software HERE.

Learn More About Advanced, Guided Root Cause Analysis

See the courses that teach advanced, guided root cause analysis at THIS LINK.

Then, see the upcoming worldwide public course locations and dates HERE.

Don’t wait! You don’t want to be on that lost wagon train.

How the Old West Was – Really

Now, here are some Western TV show videos from the 1960s. Obviously, it is an accurate depiction of real life in the 1800s. Watch and get in the mood for your guided wagon train…