Human Error Analysis

Human Error Analysis – Help Finding Human Error Root Causes

Human Error Analysis may be a misuse of terminology. Today, some people are trying to stop using the term “human error.” They say that it leads to blaming people. Here’s a sample of some articles discouraging the use of the term “human error”:

- ‘Human error’: The handicap of human factors, safety, and justice

- Human Error: A Meaningless Term

- Is ‘Human Error’ The Handicap Of Human Factors? A Discussion Among Human Factors Specialists.

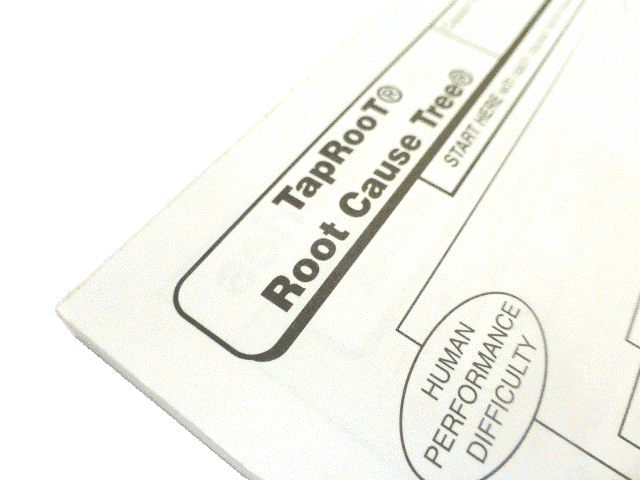

We don’t use the term “human error” on the TapRooT® Root Cause Tree® Diagram. Instead, we use the term “Human Performance Difficulty” (see below).

But if you are interested in human error analysis and finding the root causes of human errors, the TapRooT® System and the Root Cause Tree® Diagram are tools you need to learn about..

Human Error Analysis Guidance for Finding Human Error Root Causes

The TapRooT® System is proven guidance for human error analysis (finding root causes of human errors). It meets and goes beyond the fundamentals of root cause analysis. That’s why we call it “advanced” root cause analysis.

First, the TapRooT® Root Cause Analysis System starts with a process (actually two processes) and proven tools.

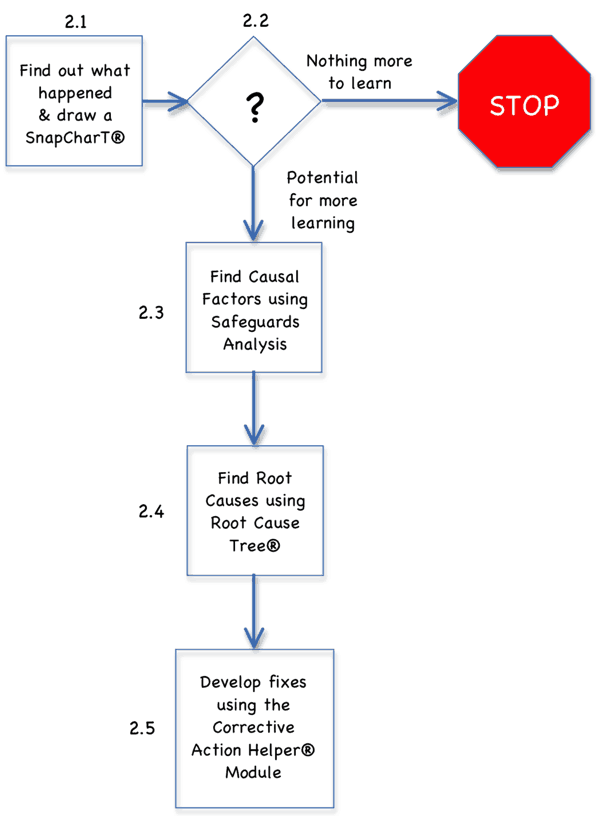

The first process is for low-to-moderate risk incidents that have the potential to be worse (precursor incidents). The process for investigating these “simple” incidents is shown below.

This process helps you perform good, fast investigations using the TapRooT® Root Cause Analysis Tools. Tools that also provide guidance. (More about that later.)

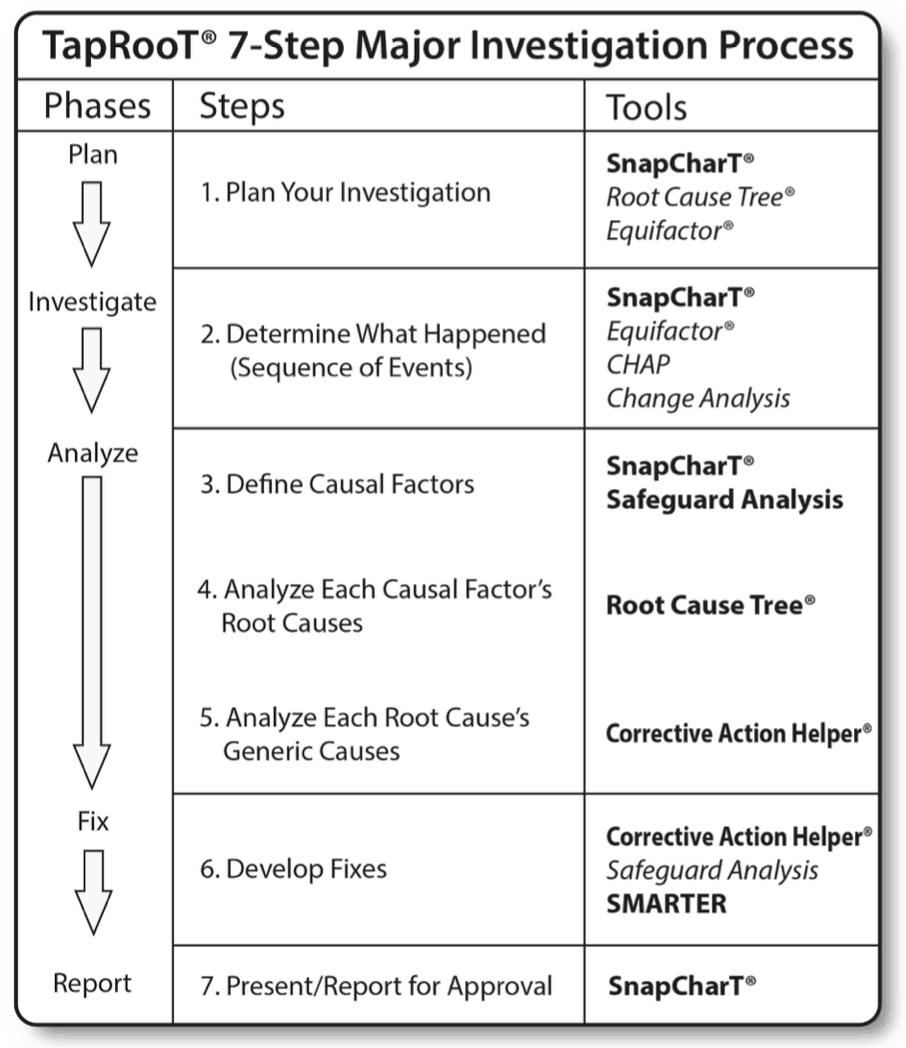

What about guidance for major investigations? You start with the process below.

This process is slightly more complex but provides the guidance needed when a major accident needs a thorough, credible root cause analysis.

Guidance from the Root Cause Tree® Diagram

Several of the tools help guide the investigator but the one we will discuss here is the Root Cause Tree® Diagram. The Root Cause Tree® is used in both of the processes above.

The Root Cause Tree® Diagram uses an expert system to guide investigators to the root causes of human errors and equipment failures.

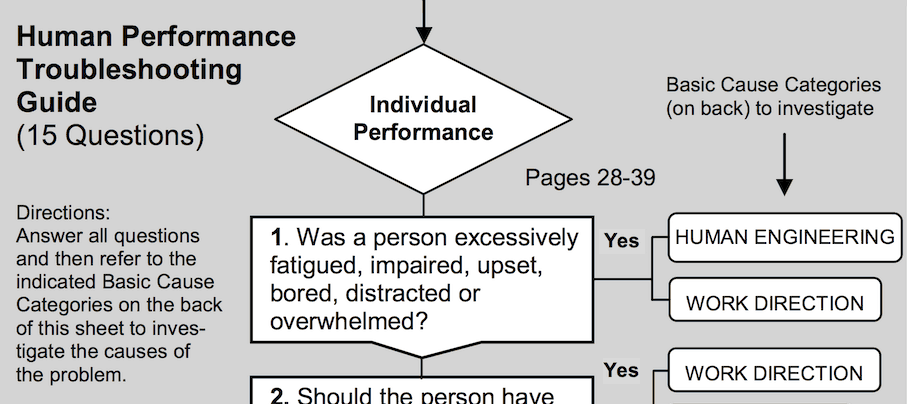

The tree has a Human Performance Troubleshooting Guide that has 15 questions to help the investigator decide where potential root causes may be lurking. What kind of questions? Questions that a human factors expert might ask. For example, see number 1 below:

Do you consistently look into fatigue, impairment, distractions as part of your investigation of human errors? That’s the kind of guidance you receive when using the Root Cause Tree®.

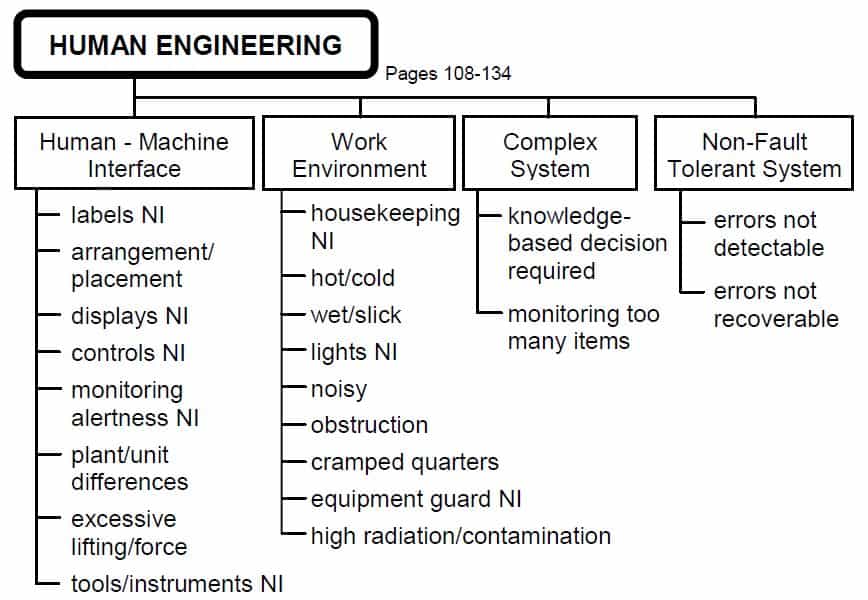

The guidance continues with the Basic Cause Categories (seven of them) on the Root Cause Tree®. An example of one category, Human Engineering, is shown below.

The terms used in the Root Cause Tree® are defined by questions that an investigator should be able to answer. These questions are in the Root Cause Tree® Dictionary and guide the investigator’s questions to answer when collecting information.

How do we know we have the right set of questions in the Guide, on the Tree, and in the Dictionary to guide an investigation? Simple … expert development, review, and testing.

Mark Paradies, Linda Unger, David Busch, and Dr. Paul Hass were among the initial developers. Their initial development was followed up by reviews by many human factors and root cause analysis experts including Dr. Charles O. Hopkins, Dr. Jens Rasmussen, Smoke Price, Dr. Alan Swain, Jerry Leaderer (first head of the forerunner of the NTSB), Larry Minnick, Heinz Bloch, Ann Ramey-Smith, Dr. Barclay Jones, and Dr. Joel Haight.

But the excellent development and initial review teams weren’t the only testing and feedback that make the Root Cause Tree® Diagram outstanding. There was extensive user testing. It started with reviews of hundreds of incidents to test the system. That was followed by field user testing. That was followed by suggested improvements and reviews by the TapRooT® Advisory Board (currently 65 TapRooT® Users from around the world).

The improvement of the Root Cause Tree® Diagram has progressed for over 30 years and continues to this day. That’s why it is such an effective human error analysis tool.

Guidance for Developing Corrective Actions

The TapRooT® System goes beyond guidance for finding root causes. It also provides guidance for developing corrective actions. How? The Corrective Action Helper® Guide.

Many times I’ve seen people do a good job identifying human error root causes but fail when it comes to developing effective corrective actions. It seems they can’t help themselves. They recommend one or more of the three standard corrective actions:

- Training

- Discipline

- Procedures

That’s why we developed the Corrective Action Helper® Guide.

It helps investigators or management develop outside-the-box answers to improve human performance.

This guidance was developed and reviewed by many of the same people involved in developing, reviewing, and testing the Root Cause Tree® Diagram, so you can be assured of the Guide’s effectiveness.

The guidance is also available in the Corrective Action Helper® Module of the TapRooT® Software.

TapRooT® Root Cause Analysis Training

If you would like to know more about the human error analysis guidance that the TapRooT® System provides, we suggest taking the 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Training. You can sponsor a course at your site or attend a public course at sites around the world.

Stopping Human Errors (a Human Error Analysis and Human Error Prevention Course)

To go beyond TapRooT® Training, you can attend another course that focuses on human error analysis and improving human performance – the Stopping Human Error Training.

What’s in the course? Here’s the course outline:

Stopping Human Error Course Outline

Day 1 (9:00am to 5:00pm)

- Foundations of Improving Human Performance

- Resilience and Safeguards

- Using TapRooT® Root Cause Analysis for Reactive Problem Analysis

- Using TapRooT® Human Performance Best Practices Proactively

- Human Engineering

- Procedures

- Training

- Communications

- Management System

- Work Direction

- Quality Control

- Stopping Normalization of Deviation

- Pre-Job Hazard Analysis

- Pre-Job Briefs

- Personal Safety Assessment

Day 2 (9:00am to 5:00pm)

- Applying Critical Human Action Profile Proactively

- Human Performance Improvement Technology

- Procedure Use/Adherence

- Place Keeping

- Independent Verification

- Three-Way Communication

- Pre-Job Brief

- Personal Safety Assessment

- Observation and Coaching

- Post-Job Brief

- Concurrent Verification

- Questioning Attitude

- Stop-Think-Act-Review

- Time Out

- Attention to Detail

- Management of Change

- Error Traps and Precursors

- Validate Assumptions

- Do Not Disturb Sign

- Conservative Decision Making

- Admiral Rickover and “Facing the Facts”

- Which Tools Will Work Best for You?

- Sample Plan/Suggested Plan

- Customizing Your Plan

- Present Your Plan, Benchmarking, and Feedback

With the exercises built-in to try the techniques, this is an active, quick-moving 2-day course.

You will leave this course with a clear understanding of methods to improve human performance and a custom plan to apply those methods at your company to achieve great gains in safety, quality, or operational and maintenance performance (all of which depend on human performance).

Participants receive the book, Stopping Human Error, a $99.95 value, as part of the course materials. In addition, participants receive a certificate of completion and a 90-day subscription to TapRooT® VI Software, our dynamic cloud-based software that computerizes the TapRooT® Techniques.

For the upcoming public in-person or virtual Stopping Human Error Courses, see THIS LINK.

To get a quote for a course at your site, CLICK HERE.