New EPA RMP Rules: 3 Years to Comply

Modification to the EPA RMP

The EPA has modified the EPA’s Risk Management Plan (RMP). To see the details of the modifications, CLICK HERE. The modifications to the regulation need to be implemented by May 10, 2027.

New Root Cause Analysis Requirements

Page 17654 of the regulation (at the link above) proposes a root cause definition, the:

“…fundamental, underlying, system-related reason

why an incident occurred.“

It requires a report documenting the incident and the root cause analysis no later than 12 months after the accident/incident.

The regulation requires using a “recognized” root cause analysis method. The EPA has not provided a list of recognized methods but states that:

“The final rule will allow the owner or operator to determine root causes using a ‘‘recognized method’’ that is appropriate for their facility and circumstance. EPA disagrees that the Agency should specify recognized investigation methods or point to specific entities for such methods. Investigation methods evolve over time, and new methods may be developed. Therefore, any list promulgated by EPA in this rule may soon be obsolete. The Agency took a similar approach in the PHA requirements for the existing rule, where it listed several potential methods, but also included the option to use an appropriate equivalent methodology. EPA recommends that owners and operators consult available literature on root cause investigation methodologies to select those appropriate for their facility and processes. For example, CCPS has published ‘‘Guidelines for Investigating Process Safety Incidents,’’ which provides extensive guidance on incident investigations, near miss identification, root cause analysis, and other related topics.”

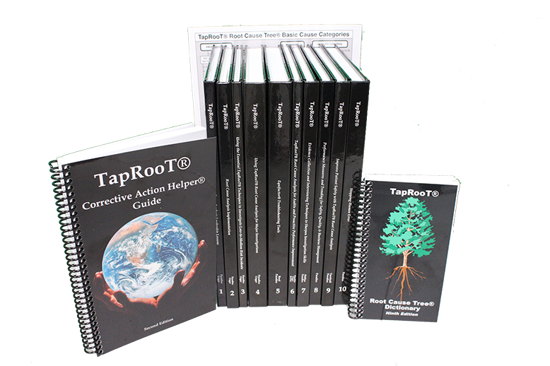

TapRooT® Root Cause Analysis is described in the book Guidelines for Investigating Process Safety Incidents and is used extensively in the oil exploration and production, refining, and chemical industries. Therefore, TapRooT® Root Cause Analysis is a recognized root cause analysis technique for people who must comply with the EPA’s RMP. Books documenting the TapRooT® System are available HERE.

Adopt TapRooT® RCA as Your Approved RCA Tool

There are many more reasons to adopt TapRooT® RCA as your root cause analysis of choice, including…

- Understanding the reasons for human errors.

- Troubleshooting equipment failures.

- Developing effective corrective actions.

- Patented, easy-to-use software.

- Effective training, both in-person and virtual.

- Extensive documentation of the TapRooT® System in the ten-book TapRooT® Book set.

- Decades of continual improvement that continues today.

- A systematic process for grading and improving investigations and investigator’s skills.

- A proven process for presenting investigations to management.

- Success stories from TapRooT® Users from a wide variety of industries.

- A worldwide network of users and a Summit to network and share best practices.

But the new regulation requiring a recognized method is certainly another good reason to adopt the TapRooT® System as your corporate standard.

To find out more about TapRooT® Root Cause Analysis Training, CLICK HERE. For someone leading an RMP-required investigation, I recommend taking the 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Training. See all of our upcoming public course dates and locations worldwide HERE. To schedule a course at your site, CLICK HERE,

If you would like more information about the advantages of TapRooT® Root Cause Analysis and a demonstration of the patented TapRooT® Software, CLICK HERE to read more and schedule an Executive Briefing and software demo. One of our Implementation Advisors will be happy to share the benefits of the TapRooT® System.