Root Cause Analysis of a Quality Issue Reported By a Whistleblower

Whistleblower Reports Quality Issue:

Can You Find the Root Causes?

How To Perform a Root Cause Analysis of a Quality Issue

Can you perform a root cause analysis of a quality issue reported by a whistleblower? The Washington Post reported this story:

Whistleblower says Navy shipbuilders ignored

nuclear submarine testing procedures for years

Where would you start?

What Happened – The Start of a Root Cause Analysis

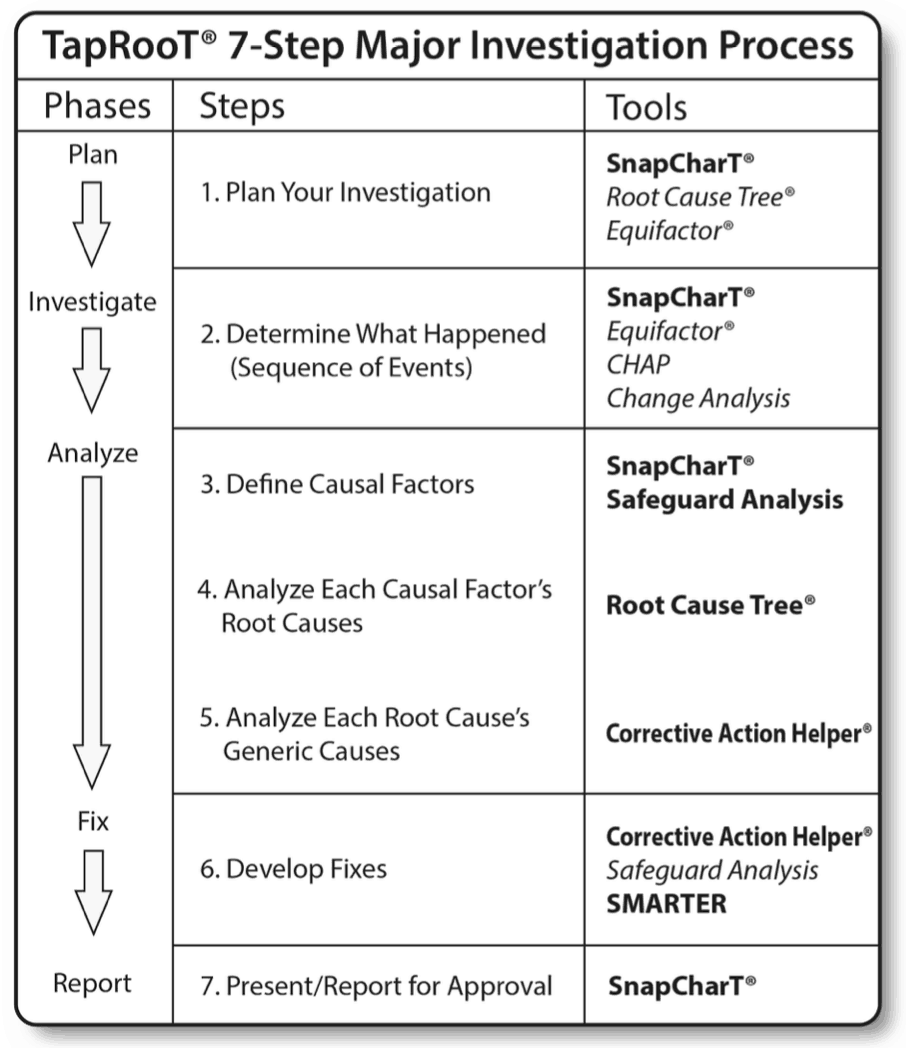

The first step of a root cause analysis of a quality issue is to draw a SnapCharT® of what you know about what happened. Since this is a major quality issue, you would be using the 7-Step TapRooT® Major Investigation Process shown below…

The first step starts with planning your investigation based on what you know and what you don’t know (displayed on your initial SnapCharT®).

What! You don’t know about the 7-Step Major Investigation Process and SnapCharT®? Then you need to attend the 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Training. Then you will be ready to perform a root cause analysis of a quality issue!

The SnapCharT® helps you organize your information and understand what happened. As you collect information, you add it to your SnapCharT® (Step 2 in the process).

When you completely understand what happened, you are ready to identify the Causal Factors leading to the Incident (in this case, a quality issue reported by a whistleblower). That’s Step 3 of the process.

Finding Causal Factors that Lead to Quality Issue Root Causes

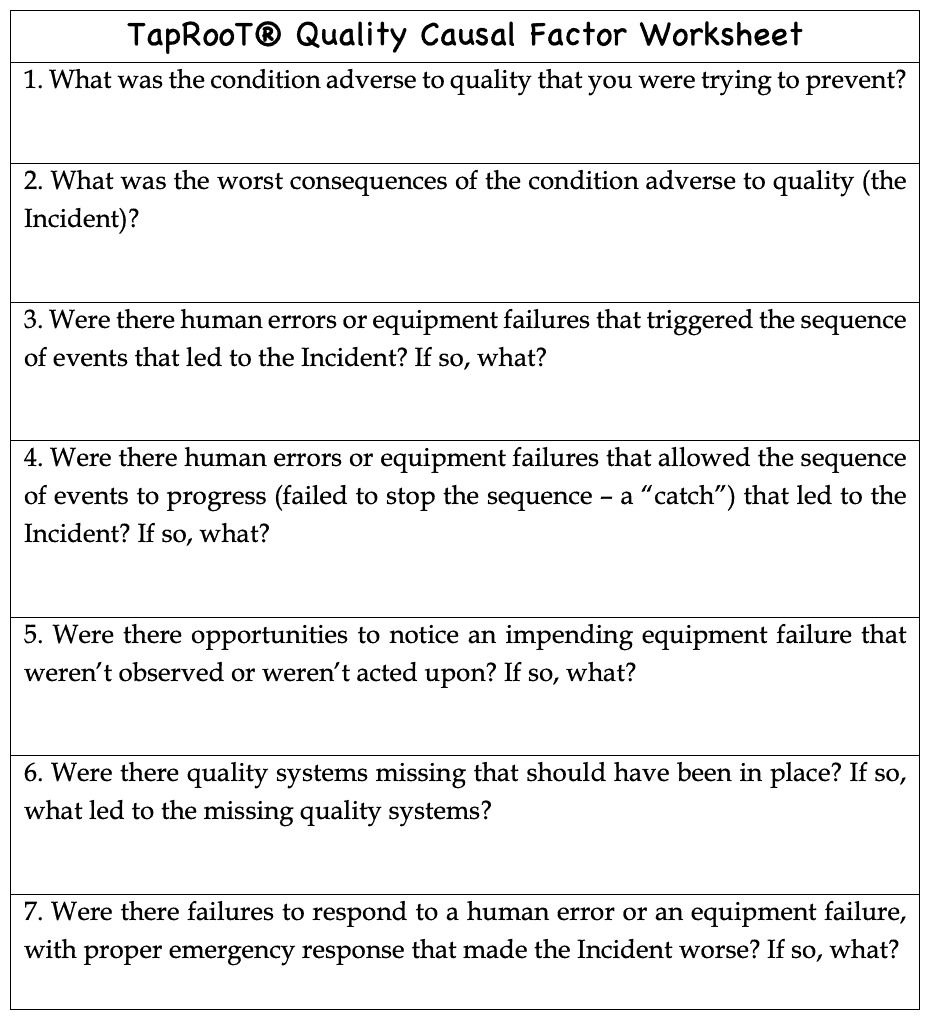

We have a new way to identify quality-related Causal Factors. It will be explained at the 2020 Global TapRooT® Summit in the Using Causal Factors Worksheets Best Practice Session. Here is a sneak-peak at the Quality Causal Factor Worksheet…

This new worksheet (and three others) are being added to the next release of the TapRooT® Software and will be built into the new TapRooT® Courses starting with the pre-Summit Courses (March 9-10).

Finding and Fixing Root and Generic Causes of Quality Issues

Steps 4-6 of the process find the root causes, the Generic Causes, and the Corrective Actions for each Causal Factor. Then, when you are almost done, you present your findings to management for approval (Step 7). That’s it! You have found and fixed the root causes of a quality issue.

Are You Fixing Your Quality Issues?

What do you think? If you perform an effective root cause analysis of quality issues, will there be anything for a whistleblower to report?

If the whistleblower reported an issue, and you had previously developed and implemented effective corrective actions, would your company be in a better position to address the complaint?

Effective root cause analysis can keep your company and management out of trouble. Want to find out more about TapRooT® and how it can help your company stay out of trouble? Attend one of our public TapRooT® Courses. Learn how to perform a root cause analysis of a quality issue. See the courses coming up around the world at THIS LINK.