Seven Ways to Learn About Equifactor® Troubleshooting

Learn More About Equifactor® Troubleshooting

Are you interested in improving equipment performance? You should be interested in Equifactor® Equipment Troubleshooting and TapRooT® Root Cause Analysis. Below are seven ways you can learn more (or teach your folks more) about Equifactor® Troubleshooting.

1. Website Page

First, CLICK HERE to visit the Equifactor® website page.

2. Articles

Next, read these articles to learn more about Equifactor®…

Or CLICK HERE for the latest articles about Equipment Reliability and Equifactor®.

3. Video

Next, watch this video…

4. Equifactor® Book

Read Book 5: Using Equifactor® Troubleshooting Tools & TapRooT® Root Cause Analysis to Improve Equipment Reliability.

To order the book, see:

5. In-Person Equifactor® Training

Finally, you can choose to attend one of our courses (view upcoming courses).

What’s in the course? Here is the course outline…

DAY ONE

- Introductions

- Understanding What Happened – SnapCharT® Basics

- SnapCharT® Exercise

- Collecting Information

- Failure Modes and Failure Agents

- Equifactor® Troubleshooting Tables

- Human Errors

- Process Troubleshooting

- Example: Troubleshooting a Seawater Pump

DAY TWO

- TapRooT®/Equifactor® Software Introduction

- Identifying Causal Factors

- Introduction to the Root Cause Tree®

- Exercise: Walking Through the Root Cause Tree®

- Exercise: Teams Find Root Causes Using the Root Cause Tree®

- Change Analysis

- Change Analysis Exercise

- Final Exercise: Solving a Major Equipment Issue

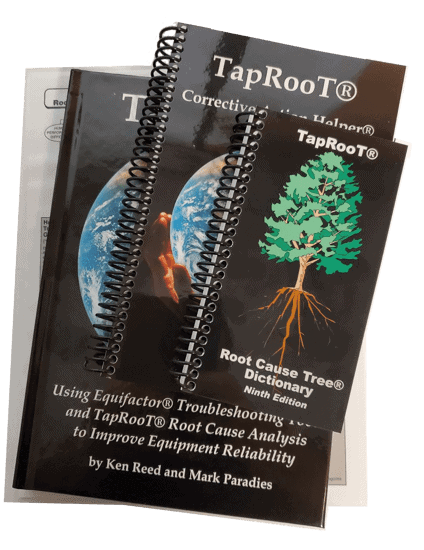

The course materials include the book, Using Equifactor® Troubleshooting Tools and TapRooT® Root Cause Analysis to Improve Equipment Reliability, a TapRooT® Root Cause Tree®, the Root Cause Tree® Dictionary, and the Corrective Action Helper® Guide, a $129 value. The book includes a complete set of Heinz Bloch’s troubleshooting tables.

6. Virtual Equifactor® Training

Can you learn Equifactor® Troubleshooting and TapRooT® ® Root Cause Analysis in a virtual course? YES! Here’s the course outline:

DAY ONE (7 HOURS)

- Class Introductions and TapRooT® Introduction

- SnapCharT® Basics – Understanding What Happened

- Software Overview

- Collecting Information

- Equifactor® Basics

- Customization

- Begin Final Exercise – SnepCharT®

DAY TWO (7 HOURS)

- Seawater Pump Example

- Change Analysis

- Causal Factors – Identifying the Error

- Root Cause Tree® – Eliminating Blame

- Root Cause Team Exercise – On your own

- Continue Final Exercise – Causal Factors and Root Cause Analysis

DAY THREE (6 HOURS)

- Corrective Actions – Developing Fixes

- Final Exercise – Putting What You’ve Learned to Work

- Final Exercise – Presentations

LEARNING ENVIRONMENT

The course will be given virtually using the Zoom online platform. However, this will be a very interactive course. Each student must have their own computer, with a webcam during the class, allowing them to see the instructor and interact with the class. There will be continuous opportunities for participation, with plenty of breaks to keep everyone engaged. Team exercises will be completed throughout the course and will utilize cloud-based TapRooT® Software.

COURSE MATERIALS

- “Using Equifactor® Troubleshooting Tools and TapRooT® Root Cause Analysis to Improve Equipment Reliability” Book

- TapRooT® Root Cause Tree®

- TapRooT® Root Cause Tree® Dictionary

- Course Workbook

- Corrective Action Helper® Guide

Upon completion of the course, attendees will receive a certificate of completion and a 90-Day Subscription to TapRooT® Personal Software, our dynamic online software that guides you through the TapRooT® process with ease and efficiency.

See the upcoming courses at THIS LINK.

7. A Course at Your Site

You can have either the in-person training or the virtual training at your site. Contact us by CLICKING HERE or calling 865-539-2139.

No matter which course you choose, we guarantee it will help you perform systematic equipment troubleshooting and find the true root causes of your equipment problems that you previously would have overlooked. Plus it will help you develop corrective actions that you and your managers will agree are much more effective.