Top 10 Improvement Goals

What Are Your Improvement Goals?

Usually, you think about your improvement goals when you are setting budgets or maybe at the start of the year. But you should be continually evaluating your goals:

- How much progress are you making?

- Do the goals align with new corporate initiatives?

- Do you need to add, subtract, or modify some goals?

- Is it time for a new approach?

To get you thinking about your goals and how you might modify or improve them, let’s start with the Top 10 Goals that would be applicable to most TapRooT® Users and see how they might apply to your company.

Once you have contemplated your goals, I have a suggestion for you to consider for each goal.

Let’s review the top 10 goals of TapRooT® Users.

Top 10 TapRooT® User Improvement Goals

1. Improve Performance: Improve safety to eliminate fatalities and serious injuries. (If you are at a hospital, you might modify this goal to be: “Improve patient safety to eliminate sentinel events.” If you are responsible for equipment reliability you could say: “Improve equipment reliability to eliminate unexpected key equipment downtime.” If you are responsible for quality, you might say: “Improve quality before a major quality issue impacts a customer.”)

2. Improve management support for improvement initiatives.

3. Improve employee participation in improvement initiatives.

4. Motivate people to exhibit positive behaviors that result in success at work.

5. Learn proven best practices from industry leaders to apply to your improvement initiatives to make them more effective.

6. Improve corrective actions so that problems never repeat once investigated, and fixes are implemented.

7. Learn how to stop the “normalization of deviation.”

8. Develop proactive performance measures to understand trends in safety, equipment reliability, and production performance before accidents or incidents occur.

9. Become a better TapRooT® User to continuously improve your root cause analysis.

10. Identify the gaps in improvement initiatives and find ways to turn those gaps into strengths in the future.

These top ten goals are rather safety oriented, but if you are responsible for equipment reliability, quality, production, patient safety, you can modify the goals with your improvement efforts in mind and the “safety” list can be converted into a patient safety list, an equipment reliability list, a quality improvement list, or a lean/production efficiency list.

Review Your Goals

Now, how many of these goals match your current goals?

Should you adopt some of the goals above?

How are you meeting your current goals?

Are you confident you will meet your goals in the next year or two?

Improvement Ideas…

GOAL 1. Improve Performance

Stopping significant injuries and fatalities (or any of the other potential improvements) is a great goal. This should be a normal part of doing business.

You might ask…

What is the best way to stop serious injuries and fatalities?

The answer? Use advanced root cause analysis to analyze and find the root causes of accidents and precursor incidents. Also, advanced root cause analysis should be used proactively to audit/assess areas with significant injury risk.

The first two (performing investigations) are easy. Read these articles to see how you can apply TapRooT® Root Cause Analysis to precursor incidents and major accidents:

Precursor Incident Investigation

Major Accident Investigation Example

How about using TapRooT® proactively? There is a book and a course.

The book…

Order it by clicking HERE.

The course:

2-Day Auditing & Proactive Improvement Using TapRooT® RCA

Here are some additional improvement ideas…

- EQUIPMENT RELIABILITY: If you are interested in improving equipment reliability, attend the 2-Day Equifactor® Eqipment Troubleshooting and TapRooT® Root Cause Analysis Course. See the upcoming public courses by CLICKING HERE. The Equifactor® Techniques are based equipment expert Heinz Bloch’s experience and have been proven effective. Also, people interested in improving maintenance and equipment reliability should consider attending the Maintenance & Reliability Best Practices Track at the Global TapRooT® Summit.

- PATIENT SAFETY: Improving patient safety has been a focus of the System Improvements and TapRooT® RCA since the mid-1990s. If you haven’t already attended a TapRooT® Course, now is the time to register for one of our courses held around the world. CLICK HERE for upcoming public course dates and locations.

- QUALITY/OPERATIONS: If you would like to apply TapRooT® to improve quality or add it to your Lean/Six Sigma Program, then you should attend one of our public TapRooT® Courses. Also, consider attending one of the eight Best Practice Tracks at the Global TapRooT® Summit. See all the tracks HERE.

GOAL 2: Improve Management Support for Improvement Efforts

One thing that improvement managers must realize is that it is NOT senior management’s job to stay excited about an improvement program. It is the improvement program manager’s job to keep management excited by demonstrating what the program is doing for them and how the improvement efforts are helping them meet their objectives.

This is especially true if there is an economic/industry downturn. People have told me that travel and training budgets get cut because management doesn’t understand the program’s value. Senior management may unintentionally send the message that improvement efforts are NOT a top priority.

If you don’t continually show management the value that improvements are producing, you will have to remind management that cutting back on improvement is expensive because of the costs of poor quality, accidents, equipment failures, and production upsets.

Two things to consider if you are a TapRooT® RCA User…

1. You should have a roadmap to success that management has participated in developing. What is a roadmap to success? Here is a video about our executive briefings and developing a roadmap to success…

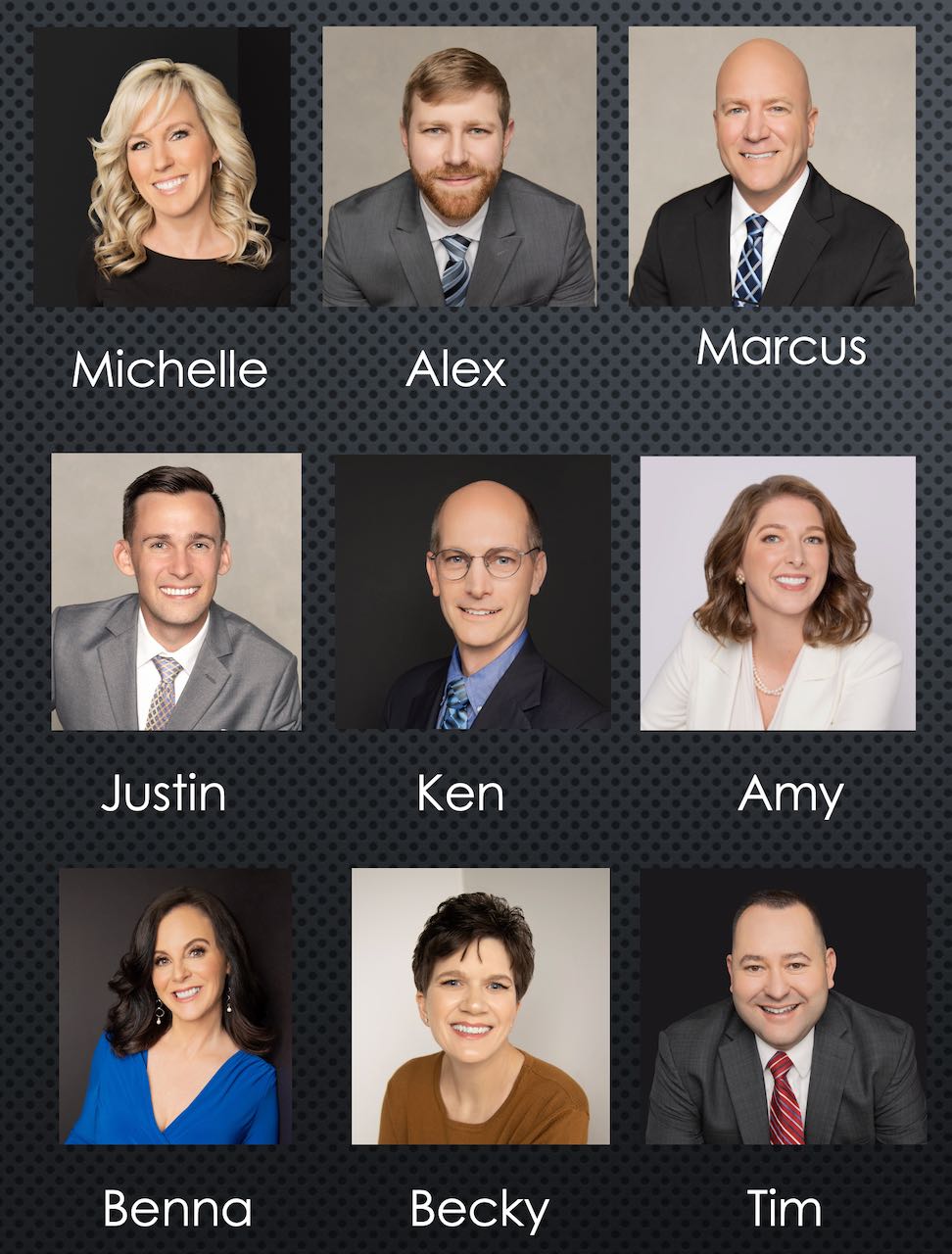

If you would like help developing your roadmap, call us at 865-539-2139 to talk to one of our Implementation Experts.

2. Your management must know their role in root cause analysis and performance improvement. We have a course to help with that. The TapRooT® Executive Leadership’s Role in Root Cause Analysis Workshop has received very favorable critiques from senior manager attendees. To find out more, CLICK HERE or call us at Alex or Tim at 865-539-2139.

GOAL 3: Improve Employee Participation in Improvement Initiatives

If your employees don’t seem involved in improvement efforts, maybe it is because you haven’t provided the opportunity.

Have you trained your employees to use advanced root cause analysis to solve problems and to use the same tools proactively?

If you need your employees fully committed to improving, give them the necessary tools. Have an on-site TapRooT® Root Cause Analysis Course. Call us at 865-539-2139 or CLICK HERE to request more information about on-site training.

GOAL 4: Motivate People to Exhibit Positive Behaviors that Result in Success at Work

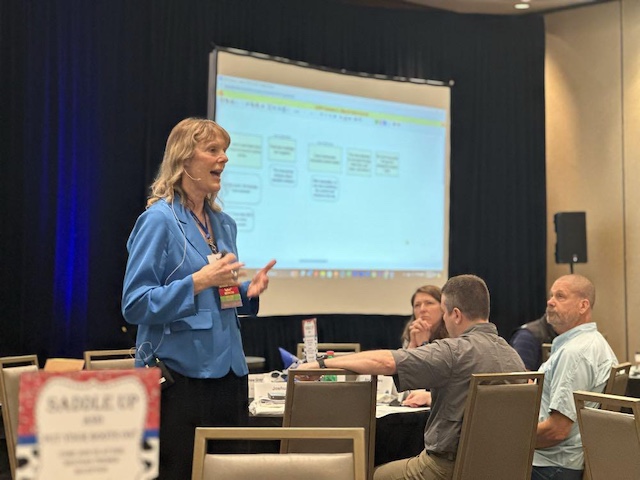

Motivating people is a difficult topic. That’s why we have the Psychology of Improvement Best Practices Track at the Global TapRooT® Summit. What are the sessions in the Psychology of Improvement Best Practices Track? Click on the figure below for more information.

GOAL 5: Learn Proven Best Practices from Industry Leaders to Apply to Your Improvement Initiatives to Make Them More Effective

How can you learn about new best practices from inside and outside your industry? Inside and outside your profession? From companies around the world?

Two standard methods are:

- Industry/professional trade magazines.

- Industry/professional conferences.

There are some excellent conferences to consider in any industry/profession. But, I’ve found that even at the best of these conferences, there tends to be industry or professional silos. For example:

- Oil industry folks tend to learn best practices from the oil industry,

- Quality folks tend to meet and share best practices with quality folks,

- Nuclear industry folks learn from the nuclear industry,

- Aviation … aviation,

- Healthcare … healthcare,

- Manufacturing … manufacturing,

- Equipment reliability … equipment reliability,

- Safety … safety,

- And so on…

Also, we then tend to look inside our own geographic area/culture/language. US people attend conferences in North America. Europeans … Europe. Australians … Australia.

That’s why we created the Global TapRooT® Summit: We wanted to do something different, something that crosses geographic, industrial, and professional boundaries and creates an environment where benchmarking and sharing experiences are fun.

Participants’ feedback after every Global TapRooT® Summit indicates that we’ve done a very good job of that.

For example:

- A process safety person from a chemical plant learns best practices from a licensing engineer in the nuclear industry.

- A healthcare quality improvement professional learns best practices from a flight safety professional.

- A nuclear safety engineer learns things from an equipment reliability specialist from a foundry.

- An equipment reliability expert learns best practices from a veteran of the Nuclear Navy.

Not only do they learn, but they have a good time doing it!

That’s why I’ve had many TapRooT® Summit participants tell me that the Summit is the BEST networking experience that they have ever had – better than any industry conference they attended.

Thus, if you haven’t yet met your goal of learning valuable best practices that you can implement to keep your improvement program fresh and progressing, you should consider attending the Global TapRooT® Summit. See all the track schedules at THIS LINK.

GOAL 6: Improve Corrective Actions so that Problems Never Repeat Once Investigated and Fixes are Implemented

How is your CAPA program preventing repeat incidents? Here are several improvement suggestions…

- Perform better root cause analysis. If you haven’t taken a TapRooT® Root Cause Analysis Course, take one SOON! See the dates and locations for public TapRooT® Courses HERE. Or get a quote for a course at your site by CLICKING HERE.

- If you already use TapRooT® RCA and want to improve your skills, register for a 5-Day TapRooT® Advance Root Cause Analysis Team Leader Course. See the course details (which should convince you to attend) at this LINK.

- TapRooT® Users should attend the Global TapRooT® Summit. There, you can learn about the latest improvements in the TapRooT® System and share best practices with other TapRooT® Users from around the world.

- There are several a pre-Summit Courses that you can attend to improve your investigations and corrective actions. See the complete list of pre-Summit Courses HERE.

At least one of ideas above should help you jumpstart efforts to improve your investigations and corrective actions and meet your goals.

GOAL 7: Learn How to Stop the “Normalization of Deviation”

Normalization of deviation is a hot topic. We have written a series of articles on this topic. See the overview of the articles (and links to each article) at:

Stopping the Normalization of Deviation with the Normalization of Excellence –

How Admiral Rickover Did It

We have added a new best practice track to the Summit that you may also find valuable. It is titled:

High-Reliability Organization Best Practices Track

What topics are included in this track? Click on the figure below for more information…

GOAL 8: Develop Proactive Performance Measures to Understand Trends in Safety, Equipment Reliability, and Production Performance Before Accidents or Incidents Occur

We wrote the book on this topic. If you need to improve your efforts, read Performance Measures and Trending for Safety, Quality, and Business Management.

GOAL 9: Become a Better TapRooT® User to Continuously Improve Your Root Cause Analysis

You can start your journey to performance improvement by simply attending a 2-Day TapRooT® Incident Investigation and Root Cause Analysis Course. But all TapRooT® Users know this is just the start. Practice, coaching, and advanced training are part of the journey to becoming an expert root cause investigator.

The 5-Day TapRooT® Advanced Root Cause Analysis Team Leader Training is designed to help you become a root cause analysis expert to lead teams in serious accident investigations.

But what do you do to improve your skills after you have attended the 2-Day and 5-Day Courses? There are several options.

First, every year we hold a Global TapRooT® Summit with Keynote Speakers and tracks to help you improve your performance improvement skills and learn the latest performance improvement best practices.

The Summit is an excellent source of knowledge to improve your performance improvement skills. But beyond the knowledge you learn, you will also make great contacts—friends—across many industries and professional disciplines that can help you expand your performance improvement network.

Second, before the Summit, we hold special advanced training for performance improvement experts to help them refresh and broaden their skills.

The eleven 2025 pre-Summit Courses include:

- Analyzing and Adjusting Safety Culture

- 2-Day Advanced Communication/Presentation Skills

- The Best Ways to Use Data to Improve Performance

- 2-Day TapRooT® Root Cause Analysis Training

- 2-Day Equifactor® Equipment Troubleshooting & TapRooT® Root Cause Analysis

- TapRooT® Advanced Case Study Workshop

- Stopping Human Error

- TapRooT® Software Training

- Auditing & Proactive Improvement Using TapRooT® RCA

- Interviewing & Evidence Collection

- 2-Day Developing an Incident Command System

That’s a great list of courses full of advanced knowledge to help you improve. Get more information about the courses HERE.

GOAL 10. Identify the Gaps in Improvement Initiatives and Find Ways to Turn Those Gaps into Strengths in the Future

The 2025 Global TapRooT® Summit has a session titled “Million Dollar Mastermind” that is specifically designed to help you identify and fill in the gaps in your improvement efforts.

Register for the Summit and choose the Million Dollar Mastermind session when registering.

That’s It!

That’s it. The top 10 improvement goals and many ideas to help you achieve those goals.

Do you still want to learn more about the Summit? Watch this video…

But don’t wait. Get your performance improvement program moving at the speed of light by getting the training and networking that you need to accelerate your program and your career.