What is HOP?

What is HOP? … Easy Answer

What is HOP? First off, HOP has nothing to do with jumping.

HOP is:

Human and Organizational Performance

OR perhaps

Human and Organizational Principles

But these definitions tell us nothing about what HOP really is.

In a previous article, I defined HOP as:

a philosophy and group of techniques mainly developed in

the nuclear industry to achieve peak human performance.

What is HOP? But There’s More…

But, as HOP has been “implemented” and morphed around the world, it has become more difficult to define.

I have heard one person define it as five basic, fairly self-evident principles…

- People make mistakes (and always will). It is normal.

- Blame fixes nothing.

- Context drives behavior.

- Learning is vital.

- Response matters.

These principles aren’t groundbreaking or new. They have existed for decades as a foundation of human factors. But even this simple, five-principles list varies from one HOP consultant to another.

Also, you may hear of HOP as:

- User-centered design.

- A systems approach.

- A problem-solving tool (learning teams).

- Failing safely.

Here is a video that describes HOP and the HOP principles in action…

This example also includes a pre-job safety analysis as another HOP tool that has existed for decades.

Also, the video introduces something akin to a behavior-based safety observation and stopping work when a hazard is identified.

Finally, the video provided an example of a simple learning team in action and a post-job debrief.

I’ve also heard of HOP as part of Safety II, “Doing safety differently,” or Resilience Engineering.

I’ve also heard that HOP is a “social science” and a philosophy that helps people work safer.

Since HOP grew out of the nuclear industry in North America, you might (or might not) see HOP associated with Human Performance Improvement Technology, which includes…

Several of these techniques were employed in the “good example” in the video.

Therefore, I tend to see HOP as whatever the consultant defines it as (somewhat like root cause analysis is whatever someone says it is).

HOP Advantages

Because HOP may include (depending on the consultant) many successful best practices, such as:

- Getting workers involved in problem-solving.

- Getting workers to suggest potential solutions.

- Human factors engineering.

- Facilitated problem-solving.

- Best practices for spotting hazards and reducing human error.

- Making systems resilient when a mistake occurs.

- Reducing or eliminating blame.

- Getting management to focus on effective solutions rather than blame.

Adopting HOP may help the company adopt one or more of these best practices. Adopting these best practices may be beneficial.

Problems With HOP

Because HOP isn’t a well-defined set of techniques but rather a philosophy defined by a particular consultant, the benefits (or drawbacks) of a particular HOP implementation can vary widely depending on what flavor of HOP is adopted.

What drawbacks are part of some HOP implementations?

- Learning teams can be highly dependent on the skill of the facilitator.

- Some HOP techniques in the HU Tools above can be counter-productive and increase blame.

- Workers and supervisors don’t always produce the most effective corrective actions and may suggest ideas that they have seen used before (training, procedures, and even discipline).

- Most workers have no training about human factors, the causes of human errors, or effective techniques to improve human performance. They depend on the facilitator to guide them (if the facilitator has that training and experience).

- Employees may view HOP as just another flavor of the week safety program that puts the blame and work on them since they are “empowered” to define safer work practices.

Management is sometimes convinced that HOP is the magic bullet that will solve all of their problems. Management just needs to put the workers in a room and not let them come out until they have a simple, cheap answer to stop management’s problems.

Learn to Improve Human Performance

If you would like to learn the human factors principles behind HOP and Human Performance Improvement Technology (HU Tools), maybe it is time you attended a course that does just that. The 2-Day Stopping Human Error Course.

I know the title of this course (Stopping Human Error) is controversial. After all, the first principle of HOP is that people make mistakes (and always will). Human error is normal. After all…

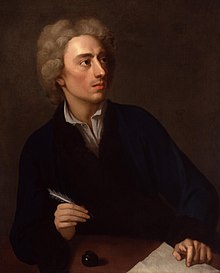

“To err is human; to forgive is divine.“

By Alexander Pope

in the poem An Essay on Criticism

But in the Stopping Human Error Course, we will show you an example of a human error likely situation being reduced from one error in 10 tries to one error in 30 tries and then to zero errors in over 1000 tries. That seems like stopping a particular human error (the reason for the course’s title).

Here is the 2-Day Stopping Human Error Course outline…

Course Outline

Day 1 (8:00 am to 5:00 pm)

- Foundations of Improving Human Performance

- Human Performance – What Should You Expect?

- Three Human Reliability Best Practices

- Mistake Proofing

- Resilience

- Safeguards

- Using TapRooT® Root Cause Analysis for Problem Analysis (Learning Teams)

- Human Performance Improvement Technology (Catch Your Own Mistakes)

- STAR

- Questioning Attitude

- Attention to Detail

- Time Out

- Error Traps & Precursors

- Validate Assumptions

- Work Direction/Finding Error Likely Situations

- Pre-Job Hazard Analysis

- Pre-Job Brief

- Personal Safety Assessment

- Post-Job Brief

- Training

- Systematic Approach to Training

- Using Procedures to Improve Human Performance

- Procedures Best Practices

- Procedure Use and Adherence

- Place Keeping

Day 2 (8:00 am to 4:00 pm)

- Communications

- 3-Way Communication

- Do Not Disturb Sign

- Management System

- Conservative Decision Making

- Stopping Normalization of Deviation

- MOC

- Quality Control

- Independent Verification

- Concurrent Verification

- Human Factors Engineering

- Best Practices (Spot Bad Practices)

- Proactive Use of CHAP

- Hazard/Target Elimination or Substitution

- Improvement Exercise

- What Should You Improve/Which Tools Will Work Best for You?

- Sample Plan

- Present Your Plan (Benchmarking/Feedback)

You will leave this course with a clear understanding of methods to improve human performance and a custom plan to apply these methods at your company to achieve significant gains in safety, quality, or operational and maintenance performance (all of which depend on human performance).

When and where is the next course? CLICK HERE to find out.

If you have any questions, please contact Alex Paradies at 865-539-2139 or by CLICKING HERE.

Would like to know more about HOW to address the HOP tenants.