Why Corrective Actions Fail

Why Don’t We Fix Problems?

We will not mention the problem of people not finding the real root causes of problems as one of the three causes that we detail in this article. Why? We have written about it before so many times.

Instead, we will discuss three other common problems that lead to the failure of corrective actions to effective fix a problem. These three problems that we will discuss in more detail are:

- Jumping to conclusions with no root cause analysis.

- Zero commitment to really fix problems.

- People use the same old corrective actions they have always used.

Precursor Incidents Provide Warnings

I have never seen a major accident that wasn’t preceded by several or maybe dozens of minor incidents that were caused by the same factors that lead to the major accident. If these precursor incidents had been investigated, the root causes identified, and effectively fixed, the major accident would have been prevented. Therefore, effective fixes for precursor incidents are critically important.

Instead, what do we see? Precursor incidents repeat because of ineffective fixes. That’s why understanding and fixing the causes of ineffective fixes is so important.

Reason 1: Jumping to Conclusions

Jumping to the fix without analysis is common. You have probably heard people say:

“I know how to fix that!”

with ZERO analysis.

The bad news is that sometimes they are right. This reinforces their behavior that we sometimes call:

Jumping to Solutions

If you see this happening, a good strategy is to ask:

“How do you know that will work?”

Sometimes people think the problem is so simple that it doesn’t deserve root cause analysis. And this can be true. However, precursor incidents deserve a real root cause analysis because, with one or two more failed Safeguards, they could have been a major accident. Therefore the deserve at least the bare minimum of an investigation…

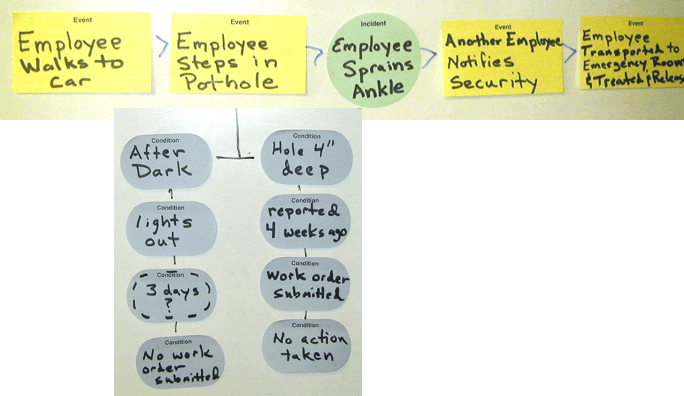

The diagram above is the process for simple investigations (using the essential TapRooT® Techniques. You can see that at a minimum, you need to find out what happened and draw a SnapCharT® Diagram BEFORE you decide that there is nothing more to learn. Often you will find that there is more to be discovered.

Let’s say this was our initial SnapCharT®…

Should we continue to investigate or stop?

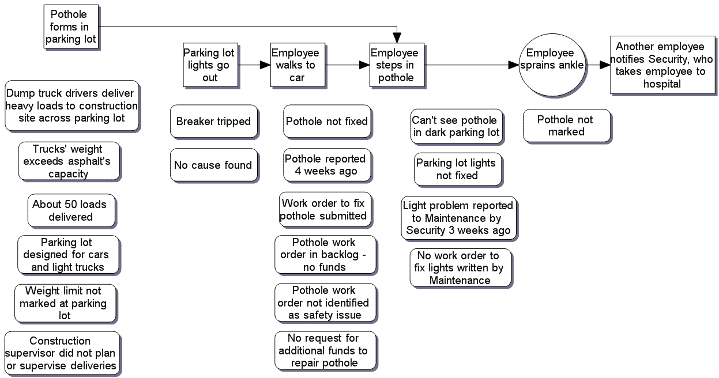

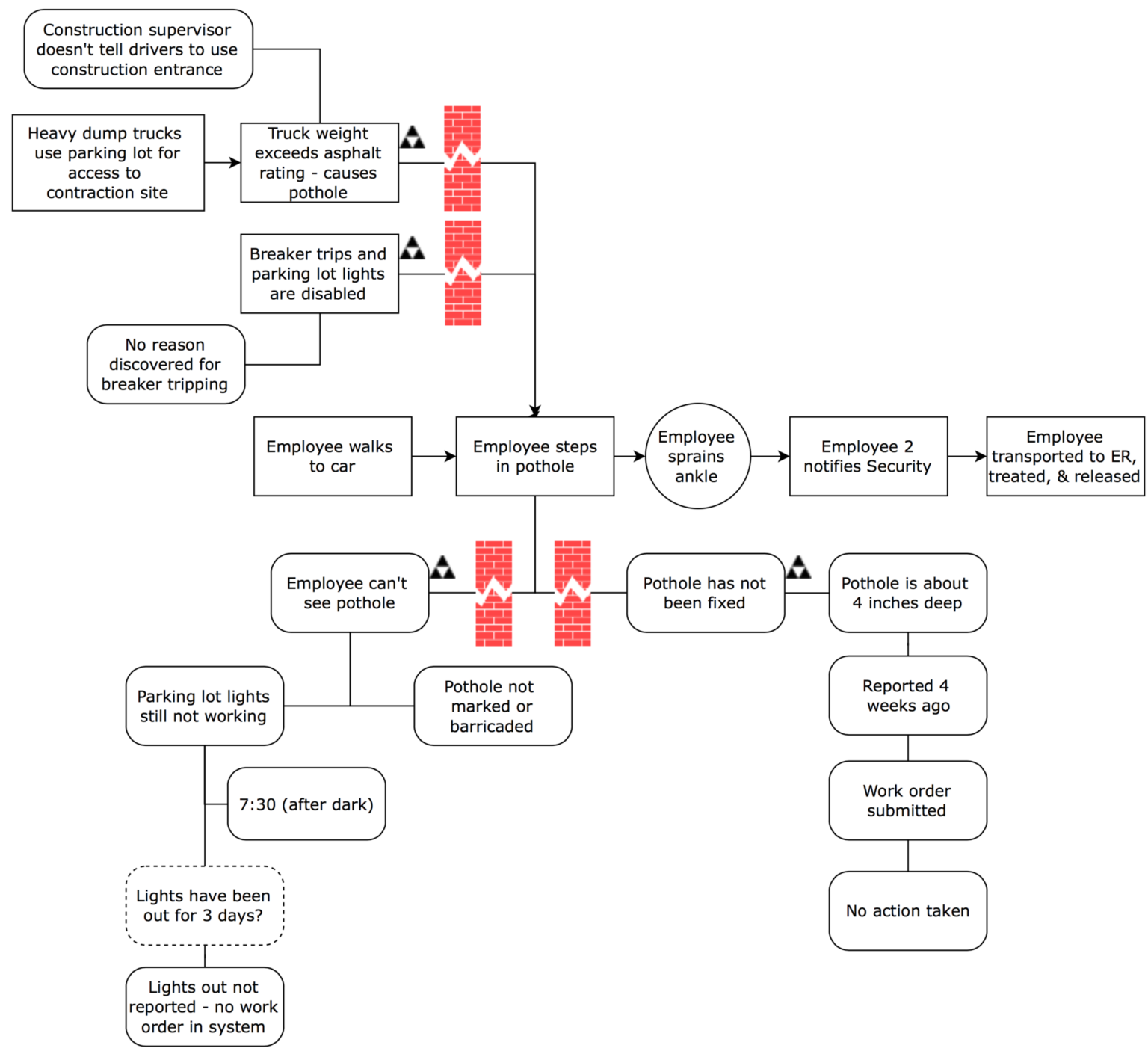

If you continued to investigate and added the facts you collect to your SnapCharT®, it might look like something like this…

And eventually will look like this when you have identified the Causal Factors…

This incident would probably never become a major accident. But there was valuable learning that could occur and effective corrective actions could help prevent future lost time injuries.

Therefore, you should always collect the facts BEFORE “Jumping to Solutions.”

Reason 2: Zero Commitment to Really Fix Problems

The Definition of Insanity:

Doing things the same way

and expecting a different result.

Sometime management doesn’t want to change. They may have many excuses:

- We don’t have the budget

- The union won’t let us.

- The regulator won’t let us.

- The lawyers won’t let us.

- The ROI is too low.

- You can’t fix every problem.

- We’ve always done it this way.

- It can’t be done any other way.

When leadership consistently expresses these ideas, employees learn to suggest quick, easy fixes that cause the least disruption.

This is probably the hardest problem to solve because change resistant managers seldom suddenly realize that they must lead effective change. Thus, precursor incidents don’t get effectively fixed. They happen over and over. Sometimes management concludes that they CAN’T be fixed.

The result? Eventually a major accident happens. In this case, the resistant managers may be fired. But don’t be fooled into this is an effective fix. The next set of managers, raised in the same culture, may have the same attitude. They may say…

“If only we could hire better employees that would be

more careful, these incidents wouldn’t happen.”

Ahhh … The old “be careful” corrective action. A definite sign that management doesn’t want to change.

Reason 3: People Use the Same Old Corrective Actions They Have Always Used.

What are the same old corrective action? We call them the Standard Three:

- DISCIPLINE: This usually starts by warning the individual to “be more careful.” Next, it escalates to the progressive discipline system. If the employee doesn’t “straighten up and fly right,” they get fired.

- TRAINING: This can be a special form of discipline if your training is bad enough. Have you ever seen someone threatened with being “sent back to training?”

- PROCEDURES: If you don’t have one, right one. If you already have a procedure, make it longer.

The reason people keep suggesting these corrective actions is that management accepts them. Thus the investigators think this is the way to fix problems. They can’t see”outside the box.”

What is the box?

Above is the box example from an old course on problem solving that I went too back in the 1980s. The instructor asked the students to connect the dots using only straight lines. How many lines did it take?

Five? Four? Three? Or one?

The official course answer was four. (An arrow looking set of four lines that went “outside the box.”) Thus we were suppose to look for outside the box answers.

Another student suggested three. She used the width of the dots and skinny lines to connect all the dots with three long straight lines.

Then I suggested one really fat line. I was informed that that was cheating. Lines don’t have width. To wish I replied:

“If they don’t have width, how can you see them?”

The inability to see beyond the Standard Three corrective actions is the reason that we wrote the original Corrective Action Helper® Module/Guide. To help peoplr see solutions that were outside the box.

Using the Guide (or the module in the TapRooT® Software) is a great way to solve this problem.

What Did You Learn?

- You need disciplined, systematic root cause analysis before you “jump to solutions.”

- Management needs to be committed to improvement.

- You need to help people see “outside the box.”

At least items 1 and 3 are fairly easy to fix. Just start using TapRooT® Root Cause Analysis – a disciplined, systematic root cause analysis tool – with the Corrective Action Helper® Guide/Module built into the process.

Item two requires management to want to change and implement effective corrective actions. That may be harder to achieve.

To explore the courses that teach TapRooT® Root Cause Analysis, CLICK HERE.

My experience is that if you say to someone, ‘think outside the box’ or look for an outside of the box solution, they don’t know how to do that. Better to say to them, in an ideal world, how can you solve the problem and then go through the barriers to the ‘ideal world solution’ and alleviate them. I’ve also found that workers often think ‘outside the box’ when under pressure to achieve something like a production goal or near-impossible deadline. This sometimes means they do something quite unexpected which allows them to achieve the goal but often without thinking about any increased hazard exposures or safety risk that comes with that.